Ed Potoczak, Director of Industry Relations, IQMS09.01.17

The Food and Drug Administration (FDA), healthcare organizations, and physicians continue to improve long-term patient outcomes for surgeries and treatments, with three-dimensional (3D) digital technologies becoming an innovative solution.

Dramatic progress has been made in the last two years with 3D organ simulations as well as individualized 3D printing with plastic resins and collagen media. Many of these software tools and physical devices are now leaving research centers and migrating to medical offices and centers for more common use. This first wave of customized medicine is being followed by a second wave of additive manufacturing involving 3D printing of metal.

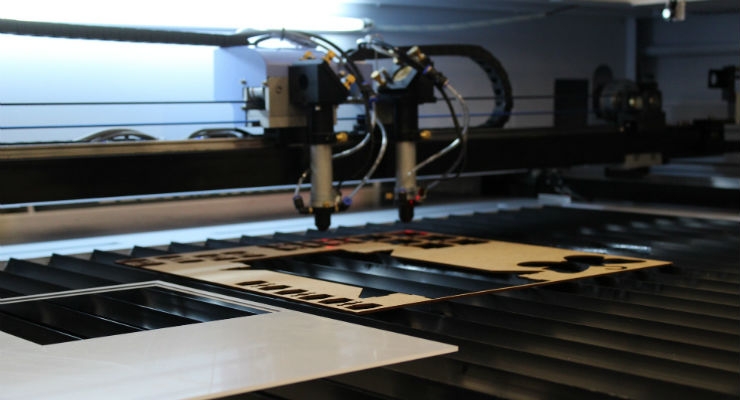

The use of 3D metal printing is well-suited for sophisticated designs not readily produced by casting, machining, or mechanical pressing, such as forging, stamping, rolling, and spinning. For designs that require intricate channels, wispy structures, and hidden passages, direct metal melting (or sintering) 3D printing can produce these parts from 3D computer-aided design (CAD) models based on digital images from non-invasive patient diagnostic scans.

Further research and testing is being requested for orthopedic 3D metal printing processes and materials before broad commercialization will occur. However, as manufacturers look to future opportunities for growth, it is helpful to understand the associated technologies, advantages, risks, and costs this approach offers. Since this technology is in development and beginning to emerge in field tests, it is important to carefully consider the market potential, return on investment (ROI), and infrastructure and systems needed to efficiently manage these new manufacturing operations.

Emerging Orthopedic Applications

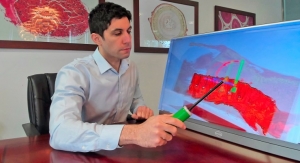

Orthopedic implant and device manufacturers can now respond quickly to requests for custom-made metal parts, using 3D printing techniques to produce tailored implantable devices, such as artificial joint parts based on high-resolution medical patient scans. These patient-matched devices can be made to exacting specifications in an accurate size and shape, with very tight tolerances to ensure an optimal fit inside the patient. The latest implants have surface features and porosity designed to let bone and tissue grow “into” the implant. Improving the bond strength of the artificial joint to natural bone and connective tissues in this way offers the potential to reduce reliance on adhesives and fasteners, ultimately enhancing patient outcomes.

Additionally, there are a number of research and development efforts around creating ultra-lightweight, space frame style printed exo-prosthetic legs, arms, and feet. This customization and reduction in mass enables wounded veterans and medical amputees to “operate” their artificial limbs in a more natural way with less fatigue.

Even metal surgical instruments can be custom printed to help make surgeries more efficient with less tissue damage.

Leading 3D Metal Printing Technology: Sintering

The 3D metal printing technology offering the greatest medical promise is direct sintering. These printing systems are able to produce strong, intricate shapes by melting metal powders with high energy sources, such as lasers and electron beams. After each thin layer of powder is wiped across the printer “bed,” the beam precisely traces a cross-sectioned pattern of fused material. Because the energy source is a very narrow beam (1 mm or less in diameter), this methodology enables the extreme accuracy of dimensions, intricate internal structures, and device surface finishes needed for personalized implants, prosthetics, and surgical instruments.

At present, the most widely used metal powders are stainless steel and titanium. But as sintering technology matures, there is continuing research and development of other metal powders—including other steel alloys, nickel, cobalt, chrome, and Inconel—to meet the needs for lightweight devices to be carried inside or outside a patient’s body.

Implantable devices, such as joint replacement components, which experience physical stresses and long-term exposure to patient body fluids and tissues, require 100 percent purity of material and quality of structure to ensure patient comfort, safety, and performance over time. The relatively high cost to produce individual, patient-customized devices that meet these requirements can be justified by the savings achieved. These include more efficient surgical procedures, faster patient recoveries, and reduced risk of joint failure compared to those associated with classic manufacturing methods, such as casting, forging, and/or machining.

Managing Sintering Safety

3D metal printers require high precision and extremely accurate control of the energy sources to ensure safety and product quality as layers of very fine powder are melted. Most popular powders are volatile by nature, and can result in explosions or flash fires in the presence of an intense flame or spark in open air. So, it is critical to take extra care in handling powder and loading 3D metal printer hoppers through the use of electrostatic grounding systems to prevent accidental sparks. Typically, a chamber that is vacuum-sealed or filled with special inert gas will house the printing mechanism to prevent contamination from flashes or floating particles, such as lint or hair. Additionally, operators and material handlers should be required to wear safety suits and gear for extra personal protection.

Newer Additive Approach – Jet Binding

Another 3D printing technology with future promise for specialized products is based on a different metal additive manufacturing process. This process, called jet binding, requires less equipment investment and can produce parts at higher speeds in a relatively safe, open-air manufacturing environment.

Jet binding is a hybrid method where a liquid resin binder is precisely sprayed onto layers of metal powder with a print head similar to an ink jet print head. As the resin-filled metal powder builds up layer by layer, the resin is cured by a low-powered laser or ultraviolet light to ensure it holds an accurate shape. The resulting product is then sintered as a whole part in a high-temperature chamber to create higher metal densities. In some cases, post processing may be done to infiltrate additional materials and tune part properties. This technology eliminates the need for high-energy sources with sophisticated controls, so the printer mechanism usually requires a lower capital investment, and except for managing static electricity around powders, is inherently safer than direct sintering.

Determining 3D Metal Printing ROI

Material-management issues plus the cost of precise motion control and power management for high-energy 3D metal fusing sources currently make the investment in process equipment higher than most commercial quality plastic resin 3D printers, which use low-powered curing sources. Therefore, any decisions should be supported by a thoughtful investment justification study with a conservative return on investment (ROI) when considering a move to offer 3D printed metal medical devices and components to the market.

On the investment side, the ROI calculation should account for the costs and resources needed for new infrastructure and talent to setup, maintain, and operate the new printing equipment, store materials, and process orders.

In looking at benefits, it is important to consider the business value of being able to provide extremely accurate, personalized metal products with a rapid time to delivery by leveraging digitally imaged patient data models. It is also valuable to weigh the opportunities for reducing inventories of multiple sizes of common product types produced “to stock” by moving to on-demand, single-piece lean production. Finally, the calculation should take into account minimizing the risk of warranty claims and recalls, along with the associated costs.

Managing 3D Metal Printing Work Centers

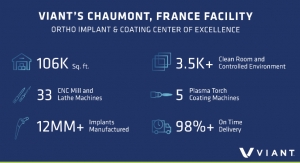

As more applications of 3D metal printing are being approved and commercialized by the FDA, costs are gradually declining. Meanwhile, the industry is seeing process improvements in printing equipment speeds, reliability, and operator safety. Together, these developments are growing the market opportunities for medical manufacturers to offer 3D printed patient-personalized metal products at commercially viable prices.

As companies add metal additive production work centers to their facilities, it is important to integrate these resources into the overall production monitoring and reporting scheme. For manufacturers in the heavily regulated medical device industry, this means applying—and potentially expanding upon—the processes for managing quality and traceability of materials and process parameters in use with their other products.

Notably, capturing data about manufacturing, packaging, and labeling transactions becomes more complex as manufacturers move into creating customized one-off products for patients. Therefore, orthopedic device makers should look at the ability to plan, schedule, monitor, and ultimately trace production using modern enterprise smart manufacturing systems to ensure quality and 100 percent accurate product identification. In doing so, manufacturers across the supply chain will be positioned to grow with a new generation of high-value and innovative printed metal orthopedic devices.

Ed Potoczak, IQMS director of industry relations, brings extensive expertise in manufacturing and engineering. He is currently a Manufacturing Enterprise Solutions Association (MESA) Americas board member, participating in the Smart Manufacturing working group. He is also certified in Design for Manufacture and Assembly, and Value Analysis/Value Engineering.

Dramatic progress has been made in the last two years with 3D organ simulations as well as individualized 3D printing with plastic resins and collagen media. Many of these software tools and physical devices are now leaving research centers and migrating to medical offices and centers for more common use. This first wave of customized medicine is being followed by a second wave of additive manufacturing involving 3D printing of metal.

The use of 3D metal printing is well-suited for sophisticated designs not readily produced by casting, machining, or mechanical pressing, such as forging, stamping, rolling, and spinning. For designs that require intricate channels, wispy structures, and hidden passages, direct metal melting (or sintering) 3D printing can produce these parts from 3D computer-aided design (CAD) models based on digital images from non-invasive patient diagnostic scans.

Further research and testing is being requested for orthopedic 3D metal printing processes and materials before broad commercialization will occur. However, as manufacturers look to future opportunities for growth, it is helpful to understand the associated technologies, advantages, risks, and costs this approach offers. Since this technology is in development and beginning to emerge in field tests, it is important to carefully consider the market potential, return on investment (ROI), and infrastructure and systems needed to efficiently manage these new manufacturing operations.

Emerging Orthopedic Applications

Orthopedic implant and device manufacturers can now respond quickly to requests for custom-made metal parts, using 3D printing techniques to produce tailored implantable devices, such as artificial joint parts based on high-resolution medical patient scans. These patient-matched devices can be made to exacting specifications in an accurate size and shape, with very tight tolerances to ensure an optimal fit inside the patient. The latest implants have surface features and porosity designed to let bone and tissue grow “into” the implant. Improving the bond strength of the artificial joint to natural bone and connective tissues in this way offers the potential to reduce reliance on adhesives and fasteners, ultimately enhancing patient outcomes.

Additionally, there are a number of research and development efforts around creating ultra-lightweight, space frame style printed exo-prosthetic legs, arms, and feet. This customization and reduction in mass enables wounded veterans and medical amputees to “operate” their artificial limbs in a more natural way with less fatigue.

Even metal surgical instruments can be custom printed to help make surgeries more efficient with less tissue damage.

Leading 3D Metal Printing Technology: Sintering

The 3D metal printing technology offering the greatest medical promise is direct sintering. These printing systems are able to produce strong, intricate shapes by melting metal powders with high energy sources, such as lasers and electron beams. After each thin layer of powder is wiped across the printer “bed,” the beam precisely traces a cross-sectioned pattern of fused material. Because the energy source is a very narrow beam (1 mm or less in diameter), this methodology enables the extreme accuracy of dimensions, intricate internal structures, and device surface finishes needed for personalized implants, prosthetics, and surgical instruments.

At present, the most widely used metal powders are stainless steel and titanium. But as sintering technology matures, there is continuing research and development of other metal powders—including other steel alloys, nickel, cobalt, chrome, and Inconel—to meet the needs for lightweight devices to be carried inside or outside a patient’s body.

Implantable devices, such as joint replacement components, which experience physical stresses and long-term exposure to patient body fluids and tissues, require 100 percent purity of material and quality of structure to ensure patient comfort, safety, and performance over time. The relatively high cost to produce individual, patient-customized devices that meet these requirements can be justified by the savings achieved. These include more efficient surgical procedures, faster patient recoveries, and reduced risk of joint failure compared to those associated with classic manufacturing methods, such as casting, forging, and/or machining.

Managing Sintering Safety

3D metal printers require high precision and extremely accurate control of the energy sources to ensure safety and product quality as layers of very fine powder are melted. Most popular powders are volatile by nature, and can result in explosions or flash fires in the presence of an intense flame or spark in open air. So, it is critical to take extra care in handling powder and loading 3D metal printer hoppers through the use of electrostatic grounding systems to prevent accidental sparks. Typically, a chamber that is vacuum-sealed or filled with special inert gas will house the printing mechanism to prevent contamination from flashes or floating particles, such as lint or hair. Additionally, operators and material handlers should be required to wear safety suits and gear for extra personal protection.

Newer Additive Approach – Jet Binding

Another 3D printing technology with future promise for specialized products is based on a different metal additive manufacturing process. This process, called jet binding, requires less equipment investment and can produce parts at higher speeds in a relatively safe, open-air manufacturing environment.

Jet binding is a hybrid method where a liquid resin binder is precisely sprayed onto layers of metal powder with a print head similar to an ink jet print head. As the resin-filled metal powder builds up layer by layer, the resin is cured by a low-powered laser or ultraviolet light to ensure it holds an accurate shape. The resulting product is then sintered as a whole part in a high-temperature chamber to create higher metal densities. In some cases, post processing may be done to infiltrate additional materials and tune part properties. This technology eliminates the need for high-energy sources with sophisticated controls, so the printer mechanism usually requires a lower capital investment, and except for managing static electricity around powders, is inherently safer than direct sintering.

Determining 3D Metal Printing ROI

Material-management issues plus the cost of precise motion control and power management for high-energy 3D metal fusing sources currently make the investment in process equipment higher than most commercial quality plastic resin 3D printers, which use low-powered curing sources. Therefore, any decisions should be supported by a thoughtful investment justification study with a conservative return on investment (ROI) when considering a move to offer 3D printed metal medical devices and components to the market.

On the investment side, the ROI calculation should account for the costs and resources needed for new infrastructure and talent to setup, maintain, and operate the new printing equipment, store materials, and process orders.

In looking at benefits, it is important to consider the business value of being able to provide extremely accurate, personalized metal products with a rapid time to delivery by leveraging digitally imaged patient data models. It is also valuable to weigh the opportunities for reducing inventories of multiple sizes of common product types produced “to stock” by moving to on-demand, single-piece lean production. Finally, the calculation should take into account minimizing the risk of warranty claims and recalls, along with the associated costs.

Managing 3D Metal Printing Work Centers

As more applications of 3D metal printing are being approved and commercialized by the FDA, costs are gradually declining. Meanwhile, the industry is seeing process improvements in printing equipment speeds, reliability, and operator safety. Together, these developments are growing the market opportunities for medical manufacturers to offer 3D printed patient-personalized metal products at commercially viable prices.

As companies add metal additive production work centers to their facilities, it is important to integrate these resources into the overall production monitoring and reporting scheme. For manufacturers in the heavily regulated medical device industry, this means applying—and potentially expanding upon—the processes for managing quality and traceability of materials and process parameters in use with their other products.

Notably, capturing data about manufacturing, packaging, and labeling transactions becomes more complex as manufacturers move into creating customized one-off products for patients. Therefore, orthopedic device makers should look at the ability to plan, schedule, monitor, and ultimately trace production using modern enterprise smart manufacturing systems to ensure quality and 100 percent accurate product identification. In doing so, manufacturers across the supply chain will be positioned to grow with a new generation of high-value and innovative printed metal orthopedic devices.

Ed Potoczak, IQMS director of industry relations, brings extensive expertise in manufacturing and engineering. He is currently a Manufacturing Enterprise Solutions Association (MESA) Americas board member, participating in the Smart Manufacturing working group. He is also certified in Design for Manufacture and Assembly, and Value Analysis/Value Engineering.