Israel Klain, Director, GibbsCAM Software, 3D Systems03.26.20

In 2016, Randy Theken founded Slice Mfg. Studios in Akron, Ohio, as a result of his medical implant company, NextStep Arthropedix, struggling to find contract manufacturers able to provide the services they needed. So, basically, they’re engineers who started a contract machine shop.

The Products

Slice manufactures very sophisticated, 3D-contoured devices for small- to medium-size customers requiring medical devices like acetabular hip cups, femoral stems, spinal cages, and the full complement of plates, screws, and other components that go with them. The medical implant industry requires a high level of customization because implants include a family of components with many permutations. For example, because every person is different, a spinal cage may have three or four different angles of lordosis in addition to 15 different sizes. Those permutations mean that Slice has to make hundreds of discrete components and program each component individually. Therefore, speed to program is critical.

“In our business, what’s important is speed to first good part. It's critical that we have the machine capability coupled with the software capability to work quickly,” explained Joe Lah, general manager of Slice Mfg. Studios. “Multi-task equipment is really helpful when you get into those small runs and many types of parts or many iterations/permutation of parts in a single-part family.” He added, “We're using GibbsCAM for our multi-axis machines.”

The Equipment

Slice specializes in combining 3D additive manufacturing and precision machining into its workflow. With its multi-task machining (MTM) equipment, the company provides parts in one setup from bar stock or a metal 3D-printed part. In addition, as part of its additive manufacturing capability, Slice has metal 3D printers that use implant-grade titanium powder for medical implants and a ProX DMP 300 printer they use primarily for prototyping surgical instruments and tooling.

Key benefits of multi-task machines include the ability to get at many sides without re-chucking, a single machining center and setup, and a high level of precision. Since a part doesn’t need to be handled through multiple operations, which involves repositioning the part, variability can be eliminated.

“That's important in our business,” said Lah. “I don't know that we would even have the ability to pull off some of the parts that we're making without the multi-axis equipment.”

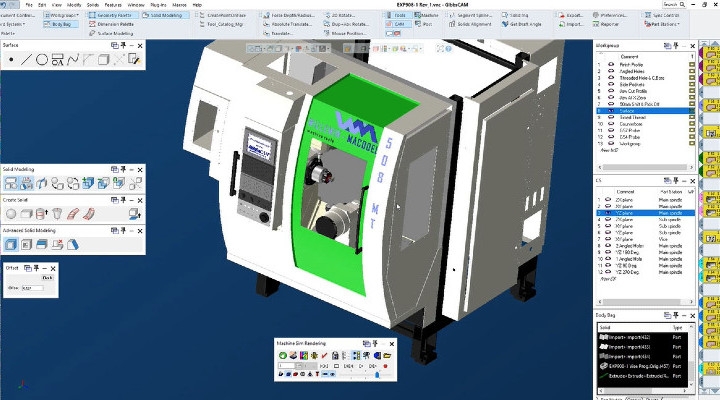

Slice has Willemin-Macodel 408 and 508 multitasking milling centers with automated parts loaders/unloaders. The Willemin-Macodel 508s are technically five-axis mill turn machines, but they’re really more like seven-axis machines with multiple spindles, vises, turrets, and a parts loader/unloader.

“They can get to five sides of any cube, which is important in a lot of these components. And with a simple grab and reposition of a vise, we can get to the sixth side of the cube. That makes it really nice when we're talking about tight tolerance, dimensions, and true positions,” said Lah.

TORNOS Swiss multi-task machine

In addition, Slice uses Tornos Swiss machines to produce bone screws, cervical screws, and high-helix threads. “There's no better piece of equipment to produce those threads. And, with full-programmable B-axis capabilities, it makes machining a whirled thread fairly simple and efficient,” said Lah. “From a precision standpoint, once you get into small, turned parts at volume with a need for a bar feeder, usually there's no better way to do it than through a Swiss lathe.”

“When choosing the Willemin-Macodel machines, it was primarily the quality aspect, precision,” recalled Lah. The Willemin 508s have high-precision spindles, linear motors, and ways outfitted with precision scales. Further, they are thermally controlled, so they hold tolerances quite well throughout the day.

“Plus, you've got robots doing things too,” added Theken. They are equipped with robotic load and pick-in-place units so Slice can essentially run lights out without quality or safety issues.

In addition, by using one machining center, they’re not inducing errors or air going from step to step or machine to machine, which is important from a quality standpoint. “When you eliminate multiple setups, you know right away whether you've got a good part or not. You don't have to rely on the stack up of tolerances that may occur from chucking to chucking, setup to setup,” explained Lah.

When using GibbsCAM to program the MTM equipment, Slice can see the part from start to finish all in one machining setup, which reduces errors inherent in multi-setup processes. Because they can simulate a part and walk through all the required tools, machining passes, and finishes in one setup in GibbsCAM, they can see things they wouldn’t be able to see or simulate with multi-stage processing. “Therefore, multitasking equipment is really the only way to go,” concluded Lah.

According to lead CNC programmer and manufacturing technician Brad Fowler, “Part quality is better. It's more accurate. It's less set up, less human error.” It also shortens lead time, according to Lah.

Since the multi-task machines are a single machining center, they have one setup. Part in, part out, part finished is much quicker than batching parts through multiple setups. Further, it eliminates the queue times between each of those setups, which can add up.

“They're really not palatable from a customer standpoint,” said Lah. “From a lead-time standpoint, we're able to meet most customer commitments in four to six weeks, whereas, if we were to batch parts through, it would probably triple that.”

Gary Knight, lead CNC programmer and manufacturing technician at Slice, said, “When you take out the other setups, it's a huge time savings. The multi-task machines save you hours of programming.”

The Software

Slice Mfg. Studios has been using GibbsCAM CNC programming software to program their multi-axis machines and some mills since they opened in 2016. “There weren't any other CAM software programs that could support the sophistication of the Willemin 508 machines,” recalled Theken.

Because any interference could wreak havoc on the MTM equipment, Slice needed CAM software that was trustworthy and repeatable. The ability to rely on the programming software is important when it comes to ultra-high-precision MTM equipment, which are not run-of-the-mill machining centers that can survive a machine tool crash. There cannot be any collisions or unexpected machine moves and a program should be able to be loaded reliably, through the post-processor, into the equipment, and move on without any concern.

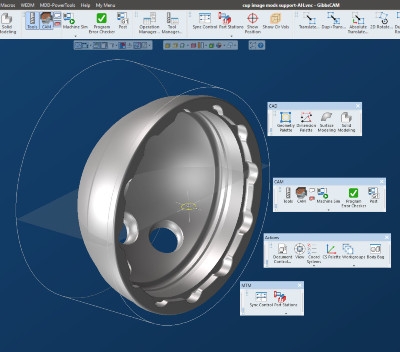

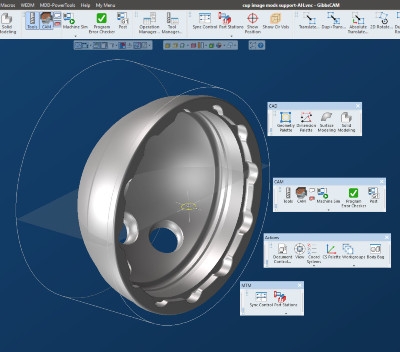

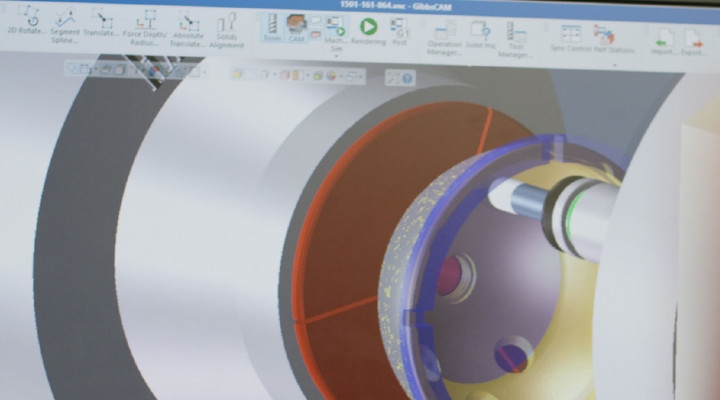

GibbsCAM customized UI

In addition to cycle time, according to Lah, the biggest selling point with the software is speed to first good part. In their industry, the time invested to take a part from drawing a model to first part out of the machine can be as much as the time to make the parts; therefore, getting through those steps quickly is critical.

By using GibbsCAM to surface different areas of the part versus traditional swarf cutting or milling and turning, Slice can produce the required geometries and surface finishes without post-processing and minimal front-side effort to get to the first good part. Lah noted, “GibbsCAM is really important to speed product through the shop. We have the confidence that any time we program a part, simulate and verify that program in the coding room, and then bring it out to the machine, we can have a part through first article layout, sometimes first try.”

Another time-saving feature of the software is its single interface. Fowler and Knight say since they don’t have to switch between multiple programs and can do everything within one interface, they're saving time. In addition, Slice saves time training new employees because they don't have to train on multiple programs.

The ability to render and simulate is another huge benefit of using the software to program multi-task equipment. Knight likes that he can model, sketch, and render all on the same screen using the software instead of wasting time flipping between screens like in previous CAM programs. “It saves several hours throughout the job.”

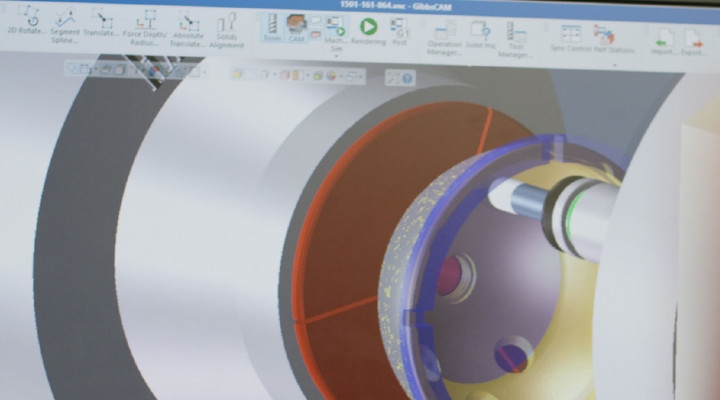

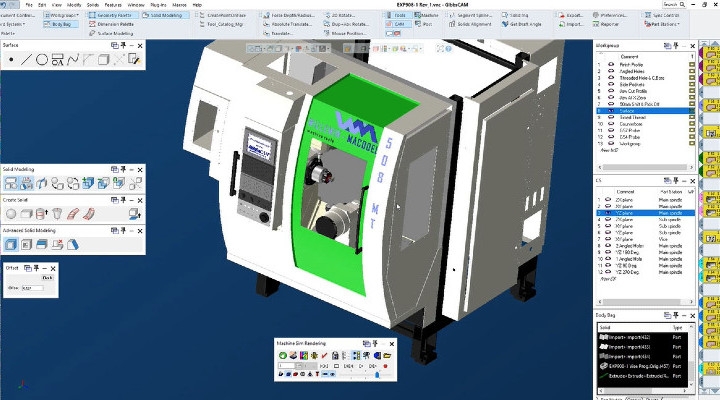

Machine simulation in GibbsCAM

In addition, the machine simulation feature helps Slice avoid machine crashes, thereby avoiding downtime and spending money to fix a crashed machine. “I've got a seven-axis Willemin machine out there and we have a lot of things moving around. And the ability to watch the simulation and make sure we're not going to crash the machine is very good,” said Fowler.

The machine simulation feature also saves the company time. Knight said he can grab a part in a Willemin 508 machine with a vise, sub-spindle, or tailstock, which he calls the wheel of fortune, and pull out whatever he needs. He can simulate that in the software and render that with the vise or sub-spindle in place. “Without GibbsCAM and being able to see the machine simulation on the parts that we render, it would be hard. You would spend a lot of time on or off the floor or checking things like clearances,” Knight said.

Machine simulation rendering in GibbsCAM

Both Fowler and Knight also appreciate that the software is customizable, and easy to use and learn. Slice was up and operational using it with their MTM equipment efficiently within hours. Fowler, who’s been using GibbsCAM since 2001, noted it has many different options to create a good toolpath. He likes that everything is up front on the same screen and he can customize the tiles so the features he uses the most are at the top of the screen.

Knight mentioned the software allows him to fine-tune the post so he can have the machine set up the way he wants. ”Obviously, anything that's a click away is going to be faster than scrolling through different tiles,” said Fowler.

According to Theken, Slice ultimately chose GibbsCAM to program their multi-task machines because of its industry experience and reputation.

Reputation

Lah noted GibbsCAM is widely known in the community. “With these multitasking machines, it's hard to find folks who can make them sing like they need to and like they can. With GibbsCAM, we can find programmers who really know the capabilities of the machine, can match that with the software, and get us to solutions that work, quickly.”

“We're using GibbsCAM for our multi-axis machines. We have some very good programmers on staff and, when we were looking to choose a software package, resoundingly, GibbsCAM was their software of choice.” explained Lah.

Post-Processor Support

Post-processor support was another critical factor in choosing GibbsCAM. According to Fowler, each machine takes a different post and, if a post doesn't match the machine, they have to edit a lot of code.

Initially, Slice was using a different post processor that was pretty unreliable. “When we teamed with Virtual Manufacturing Services Inc., things were seamless. They provided us an out-of-the-box post processor that was orders of magnitude better than anything we had used previously, that we could count on the first time, and was really instrumental to the success of our firm. We were able to go from initial post to finished state very quickly—a matter of weeks,” Lah recalled.

In addition, Virtual Manufacturing has been able to turn around any edits, customizations, or bug fixes for a post almost immediately.

Local Support

Another benefit of working with Virtual Manufacturing is they’re local. Knight had worked with Virtual Manufacturing for posts since 2006 and said the support's been great. “And I don't have to wait to contact California.”

The Results: Competitive Advantage

With the multi-task machining centers and GibbsCAM software, Slice Mfg. Studios has been able to provide its medical device and industrial customers with the complex, ultra-high-precision components they require. “We're able to, in one setup, make components that might take others months and countless hours of design and programming work. Where, through the GibbsCAM software and multitasking capabilities, we're able to go from program to finished part in days,” said Lah.

Many customers have come back with high accolades for how Slice has used their multi-axis equipment to remove pain from the customer supply chain. For example, a defense customer was sourcing a very complex part from the United Kingdom processed in four setups that had exorbitantly long lead times and a fairly prohibitive cost. Through the MTM equipment and GibbsCAM software, Slice was able to complete the part in a single setup, cutting the cycle time by 20 percent and removing three setups from the process.

In addition to the cycle time savings and the high-quality, precision machining with GibbsCAM, Slice achieved tolerances other suppliers had proven unattainable. The print came in from the defense customer with a true position tolerance of zero. The only variability Slice was allowed was through maximum material condition. “Through GibbsCAM and the MTM equipment, we were able to achieve that. And I can't think of a lower tolerance than zero,” Lah commented.

Another example Slice is pretty proud of is an acetabular hip cup for an outside customer. The customer was having the cups machined at three other independent, very high-end machine shops that all required three machining setups and about two hours of machine time to produce a cup. Slice brought the hip cup in house and manufactured it in a single setup using the MTM equipment and GibbsCAM software—reducing the cycle time by almost 80 percent down to about 20 minutes.

With GibbsCAM, Slice has taken pain away in a speed that allows their customers to continue business without worrying about the supply chain or whether they're going to meet project deadlines.

“Without GibbsCAM, I don't know how we would operate in this shop. It takes a powerful piece of software to be able to go from our customers' ideas and requirements into real, tangible solutions and products,” said Lah.

The Products

Slice manufactures very sophisticated, 3D-contoured devices for small- to medium-size customers requiring medical devices like acetabular hip cups, femoral stems, spinal cages, and the full complement of plates, screws, and other components that go with them. The medical implant industry requires a high level of customization because implants include a family of components with many permutations. For example, because every person is different, a spinal cage may have three or four different angles of lordosis in addition to 15 different sizes. Those permutations mean that Slice has to make hundreds of discrete components and program each component individually. Therefore, speed to program is critical.

“In our business, what’s important is speed to first good part. It's critical that we have the machine capability coupled with the software capability to work quickly,” explained Joe Lah, general manager of Slice Mfg. Studios. “Multi-task equipment is really helpful when you get into those small runs and many types of parts or many iterations/permutation of parts in a single-part family.” He added, “We're using GibbsCAM for our multi-axis machines.”

The Equipment

Slice specializes in combining 3D additive manufacturing and precision machining into its workflow. With its multi-task machining (MTM) equipment, the company provides parts in one setup from bar stock or a metal 3D-printed part. In addition, as part of its additive manufacturing capability, Slice has metal 3D printers that use implant-grade titanium powder for medical implants and a ProX DMP 300 printer they use primarily for prototyping surgical instruments and tooling.

Key benefits of multi-task machines include the ability to get at many sides without re-chucking, a single machining center and setup, and a high level of precision. Since a part doesn’t need to be handled through multiple operations, which involves repositioning the part, variability can be eliminated.

“That's important in our business,” said Lah. “I don't know that we would even have the ability to pull off some of the parts that we're making without the multi-axis equipment.”

Slice has Willemin-Macodel 408 and 508 multitasking milling centers with automated parts loaders/unloaders. The Willemin-Macodel 508s are technically five-axis mill turn machines, but they’re really more like seven-axis machines with multiple spindles, vises, turrets, and a parts loader/unloader.

“They can get to five sides of any cube, which is important in a lot of these components. And with a simple grab and reposition of a vise, we can get to the sixth side of the cube. That makes it really nice when we're talking about tight tolerance, dimensions, and true positions,” said Lah.

TORNOS Swiss multi-task machine

“When choosing the Willemin-Macodel machines, it was primarily the quality aspect, precision,” recalled Lah. The Willemin 508s have high-precision spindles, linear motors, and ways outfitted with precision scales. Further, they are thermally controlled, so they hold tolerances quite well throughout the day.

“Plus, you've got robots doing things too,” added Theken. They are equipped with robotic load and pick-in-place units so Slice can essentially run lights out without quality or safety issues.

In addition, by using one machining center, they’re not inducing errors or air going from step to step or machine to machine, which is important from a quality standpoint. “When you eliminate multiple setups, you know right away whether you've got a good part or not. You don't have to rely on the stack up of tolerances that may occur from chucking to chucking, setup to setup,” explained Lah.

When using GibbsCAM to program the MTM equipment, Slice can see the part from start to finish all in one machining setup, which reduces errors inherent in multi-setup processes. Because they can simulate a part and walk through all the required tools, machining passes, and finishes in one setup in GibbsCAM, they can see things they wouldn’t be able to see or simulate with multi-stage processing. “Therefore, multitasking equipment is really the only way to go,” concluded Lah.

According to lead CNC programmer and manufacturing technician Brad Fowler, “Part quality is better. It's more accurate. It's less set up, less human error.” It also shortens lead time, according to Lah.

Since the multi-task machines are a single machining center, they have one setup. Part in, part out, part finished is much quicker than batching parts through multiple setups. Further, it eliminates the queue times between each of those setups, which can add up.

“They're really not palatable from a customer standpoint,” said Lah. “From a lead-time standpoint, we're able to meet most customer commitments in four to six weeks, whereas, if we were to batch parts through, it would probably triple that.”

Gary Knight, lead CNC programmer and manufacturing technician at Slice, said, “When you take out the other setups, it's a huge time savings. The multi-task machines save you hours of programming.”

The Software

Slice Mfg. Studios has been using GibbsCAM CNC programming software to program their multi-axis machines and some mills since they opened in 2016. “There weren't any other CAM software programs that could support the sophistication of the Willemin 508 machines,” recalled Theken.

Because any interference could wreak havoc on the MTM equipment, Slice needed CAM software that was trustworthy and repeatable. The ability to rely on the programming software is important when it comes to ultra-high-precision MTM equipment, which are not run-of-the-mill machining centers that can survive a machine tool crash. There cannot be any collisions or unexpected machine moves and a program should be able to be loaded reliably, through the post-processor, into the equipment, and move on without any concern.

GibbsCAM customized UI

By using GibbsCAM to surface different areas of the part versus traditional swarf cutting or milling and turning, Slice can produce the required geometries and surface finishes without post-processing and minimal front-side effort to get to the first good part. Lah noted, “GibbsCAM is really important to speed product through the shop. We have the confidence that any time we program a part, simulate and verify that program in the coding room, and then bring it out to the machine, we can have a part through first article layout, sometimes first try.”

Another time-saving feature of the software is its single interface. Fowler and Knight say since they don’t have to switch between multiple programs and can do everything within one interface, they're saving time. In addition, Slice saves time training new employees because they don't have to train on multiple programs.

The ability to render and simulate is another huge benefit of using the software to program multi-task equipment. Knight likes that he can model, sketch, and render all on the same screen using the software instead of wasting time flipping between screens like in previous CAM programs. “It saves several hours throughout the job.”

Machine simulation in GibbsCAM

In addition, the machine simulation feature helps Slice avoid machine crashes, thereby avoiding downtime and spending money to fix a crashed machine. “I've got a seven-axis Willemin machine out there and we have a lot of things moving around. And the ability to watch the simulation and make sure we're not going to crash the machine is very good,” said Fowler.

The machine simulation feature also saves the company time. Knight said he can grab a part in a Willemin 508 machine with a vise, sub-spindle, or tailstock, which he calls the wheel of fortune, and pull out whatever he needs. He can simulate that in the software and render that with the vise or sub-spindle in place. “Without GibbsCAM and being able to see the machine simulation on the parts that we render, it would be hard. You would spend a lot of time on or off the floor or checking things like clearances,” Knight said.

Machine simulation rendering in GibbsCAM

Both Fowler and Knight also appreciate that the software is customizable, and easy to use and learn. Slice was up and operational using it with their MTM equipment efficiently within hours. Fowler, who’s been using GibbsCAM since 2001, noted it has many different options to create a good toolpath. He likes that everything is up front on the same screen and he can customize the tiles so the features he uses the most are at the top of the screen.

Knight mentioned the software allows him to fine-tune the post so he can have the machine set up the way he wants. ”Obviously, anything that's a click away is going to be faster than scrolling through different tiles,” said Fowler.

According to Theken, Slice ultimately chose GibbsCAM to program their multi-task machines because of its industry experience and reputation.

Reputation

Lah noted GibbsCAM is widely known in the community. “With these multitasking machines, it's hard to find folks who can make them sing like they need to and like they can. With GibbsCAM, we can find programmers who really know the capabilities of the machine, can match that with the software, and get us to solutions that work, quickly.”

“We're using GibbsCAM for our multi-axis machines. We have some very good programmers on staff and, when we were looking to choose a software package, resoundingly, GibbsCAM was their software of choice.” explained Lah.

Post-Processor Support

Post-processor support was another critical factor in choosing GibbsCAM. According to Fowler, each machine takes a different post and, if a post doesn't match the machine, they have to edit a lot of code.

Initially, Slice was using a different post processor that was pretty unreliable. “When we teamed with Virtual Manufacturing Services Inc., things were seamless. They provided us an out-of-the-box post processor that was orders of magnitude better than anything we had used previously, that we could count on the first time, and was really instrumental to the success of our firm. We were able to go from initial post to finished state very quickly—a matter of weeks,” Lah recalled.

In addition, Virtual Manufacturing has been able to turn around any edits, customizations, or bug fixes for a post almost immediately.

Local Support

Another benefit of working with Virtual Manufacturing is they’re local. Knight had worked with Virtual Manufacturing for posts since 2006 and said the support's been great. “And I don't have to wait to contact California.”

The Results: Competitive Advantage

With the multi-task machining centers and GibbsCAM software, Slice Mfg. Studios has been able to provide its medical device and industrial customers with the complex, ultra-high-precision components they require. “We're able to, in one setup, make components that might take others months and countless hours of design and programming work. Where, through the GibbsCAM software and multitasking capabilities, we're able to go from program to finished part in days,” said Lah.

Many customers have come back with high accolades for how Slice has used their multi-axis equipment to remove pain from the customer supply chain. For example, a defense customer was sourcing a very complex part from the United Kingdom processed in four setups that had exorbitantly long lead times and a fairly prohibitive cost. Through the MTM equipment and GibbsCAM software, Slice was able to complete the part in a single setup, cutting the cycle time by 20 percent and removing three setups from the process.

In addition to the cycle time savings and the high-quality, precision machining with GibbsCAM, Slice achieved tolerances other suppliers had proven unattainable. The print came in from the defense customer with a true position tolerance of zero. The only variability Slice was allowed was through maximum material condition. “Through GibbsCAM and the MTM equipment, we were able to achieve that. And I can't think of a lower tolerance than zero,” Lah commented.

Another example Slice is pretty proud of is an acetabular hip cup for an outside customer. The customer was having the cups machined at three other independent, very high-end machine shops that all required three machining setups and about two hours of machine time to produce a cup. Slice brought the hip cup in house and manufactured it in a single setup using the MTM equipment and GibbsCAM software—reducing the cycle time by almost 80 percent down to about 20 minutes.

With GibbsCAM, Slice has taken pain away in a speed that allows their customers to continue business without worrying about the supply chain or whether they're going to meet project deadlines.

“Without GibbsCAM, I don't know how we would operate in this shop. It takes a powerful piece of software to be able to go from our customers' ideas and requirements into real, tangible solutions and products,” said Lah.