Materialise Partners With University on 3-D Printed Tracheal Splints

Materialise Partners With University on 3-D Printed Tracheal Splints

Collaboration to focus on testing the technology in clinical trials.

Recently, Materialise entered into an exclusive licensing arrangement with the University of Michigan to take the splint through clinical trials, in order to ultimately offer the newly granted patent in the marketplace. The move is a critical step towards bringing this technology to all children suffering from this condition, company executives claim.

Dr. Glenn Green and Dr. Scott Hollister of the University of Michigan used Materialise’s Mimics Innovation Suite to model and construct these splints using computed tomography scans of patient anatomy.

“Here at Materialise, we strongly believe in the transformative power of great collaborations, such as the one we have enjoyed these past two years with Dr. Green, Dr. Hollister, and all others who have contributed to this live-saving application of 3D printing,” said Bryan Crutchfield, managing director of Materialise USA. “This collaboration is proof that when the right skill sets and technologies are combined, solutions can be found for problems once thought impossible.”

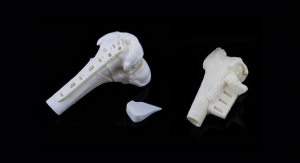

About 1 in 2,200 babies are born with TBM, which causes the trachea to periodically collapse. The tracheal splint, developed to save the lives of these children, is made with a biopolymer called polycaprolactone, a biodegradable material that is gradually absorbed into the infant’s body tissue over time.

“It was the possibility to realize 3-D-printing enabled medical applications that, in part, motivated me to start Materialise 25 years ago. Today, we are proud to offer an entire range of software and services that can help universities, research centers, medical device companies, and hospitals develop solutions that result in a better and healthier world, such as the treatment developed for children diagnosed with TBM," Materialise Founder/CEO Fried Vancraen said. "It has been an honor to work with the team at University of Michigan, who are using our Mimics Innovation Suite to truly show the impact that patient-specific, 3-D-printed solutions can have on the lives of individuals.”

The U-M team hopes to next year open a clinical trial for 30 patients with similar conditions at C.S. Mott Children’s Hospital.

“This agreement is a critical step in our goal to make this treatment readily available for other children who suffer from this debilitating condition,” Mott otolaryngologist Dr. Glenn Green said.

“We have continued to evolve and automate the design process for the splints, allowing us to achieve in two days what used to take us up to five days to accomplish,” added Scott Hollister, Ph.D., professor of biomedical Engineering and mechanical engineering at the University of Michigan. “I feel incredibly privileged to be building products that surgeons can use to save lives.”

Headquartered in Leuven, Belgium, Materialise provides additive manufacturing (AM) software solutions and 3-D printing services in various industries, including healthcare, automotive, aerospace, art and design and consumer products.Watch a video of inspiration behind the 3-D printed splint below: