Sam Brusco, Associate Editor09.14.21

“Enabling tech” is all the buzz in spine surgery—surgical planning software, computer-assisted navigation, intra-op 3D imaging, and robotic systems comprise this class of technology. They’re presently in various stages of refinement, spinal robots in particular, because they’re limited to positioning an alignment guide for pedicle screw placement.

In contrast, intra-op imaging technology has been further developed to enable accurate 3D spinal image acquisition that can be readily used for spinal navigation. Integration of these tools can maximize procedural safety, consistency, reliability, and efficacy. As such, a trend for spinal device makers is to incorporate many enabling technologies into spinal robotic systems or spine procedures in general. Advanced planning software and navigation is expected to allow wider application and value in the near future. In the long-term, enabling technologies like augmented reality could be a component of spinal robots.

Proprio, a Seattle-based computational imaging company providing enhanced visualization systems for precision tasks, has a flagship surgical navigation system that provides surgeons with an enhanced, real-time view of anatomy. This was made possible in part by the artificial intelligence (AI) solution of computer vision, which endows machines with visual recognition that mimics human sight. With the system, surgeons can view more of the patient’s anatomy, and boost situational awareness.

Extended reality (XR) first entered surgical technology through Microsoft’s Hololens. But the computer vision behind Proprio’s augmented reality solution lets surgeons view inside the anatomy while operating in real time. Proprio’s PARADIGM system is an algorithmic, real-time, multimodal image registration device that utilizes a multi-camera system. Surgeons can access pre-op imaging, powerful magnification, virtual annotation, and collaborative feedback in their field of view using the system. The system is intuitive to use as well because this perspective shifts with the surgeon.

“At Proprio, our goal is to enhance human capability and performance in medicine,” said Samuel Browd, M.D., Ph.D., co-founder and chief medical officer of Proprio. “We combine AI, XR, and computer vision to radically shift perception and create the new way of seeing. Through intuitive design and close collaboration between physicians, designers, and engineers, Proprio gives surgeons enhanced situational awareness with the objective to deliver better clinical outcomes.”

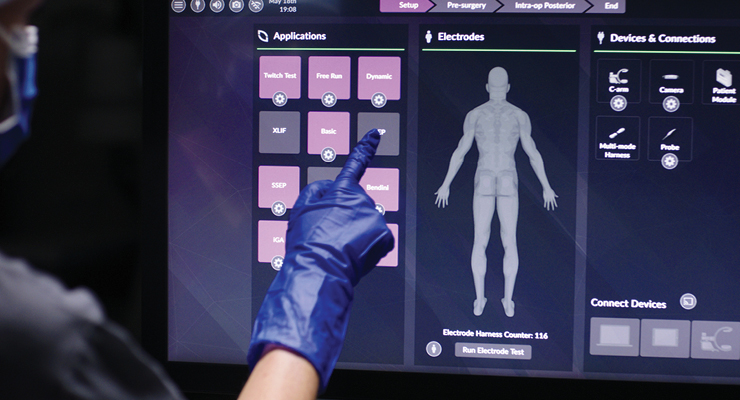

Another recent and significant advancement in spine surgery supporting technology was the FDA nod and subsequent commercial launch of global spine tech company NuVasive’s Pulse integrated technology platform at the end of July. It entered the EU market via CE mark approval earlier in the summer.

The Pulse platform aims to boost spine surgery safety, efficiency, and reproducibility via surgeon access to multiple technologies from a condensed footprint. The company’s LessRay tech increases OR efficiency through streamlined imaging workflow, and significantly reduces radiation exposure to everyone in the room. It supports various imaging systems, including enhanced integration with Siemens’ Cios Spin 3D mobile C-arm. Navigation technology helps to improve screw placement accuracy and further minimize radiation. Neuromonitoring allows automated nerve detection for reduced variability and faster neural information interpretation.

Integrated Global Alignment (iGA) provides surgical planning and intra-op assessment tools for spinal alignment correction and restoration, and surgeons can follow up post-op to assess procedural results. Bendini patient-specific rod bending creates rods bent to implant locations. Computer-assisted bend instructions expedites manual rod manipulation. And wireless connectivity capability permits all members of the OR surgical team to connect and control the Pulse platform—from surgeon, to C-arm technologist, to support staff.

“This first-of-its-kind platform supports all spine procedure types—from open to less invasive techniques,” Massimo Calafiore, NuVasive executive VP, Global Business Units, told the press. “Pulse is one of the most versatile tools in the spine OR, and the integration of multiple technologies in one platform enhances a surgeon’s capabilities to make better, more informed clinical decisions for their patients.”

“This is the culmination of years of research and development to deliver a platform that helps improve clinical, financial, and operational outcomes,” commented NuVasive CEO J. Christopher Barry. “Like we did with XLIF, Pulse is a disruptive technology that has the ability to transform not only the trajectory of NuVasive but the future of spine care for patients.”

Medtronic’s Spine Surgery Insight

Medtronic’s arsenal of spinal technologies is impressive—enough to land the company’s division in the fifth spot among ODT’s Top 10 orthopedic device companies report this year. The firm offers solutions for balloon kyphoplasty, bone grafting, cervical arthroplasty, drug infusion systems for chronic pain and severe spasticity, electrosurgical products, high-speed surgical drills and tools, intra-op neuromonitoring, nucleus removal tools, posterior occipitocervical upper-thoracic reconstructive systems, RA systems for bone tumors, spinal cord stimulators, spine robotics, SpineLine reimbursement, surgical imaging and navigation systems, an expandable corpectomy system, tumor management, and vertebroplasty.

ODT recently had the pleasure of speaking with Carlton Weatherby, vice president and general manager of spine and biologics at Medtronic, for an inside look into what his company is doing to further innovate in spine surgery.

Sam Brusco: How is Medtronic’s technology addressing unmet clinical needs for spine surgery?

Carlton Weatherby: Ultimately spine surgery is still more art than science, and the clinical goal and objective is reducing variability in clinical outcomes to ensure patients can go in confidently into a procedure, where surgeons perform and execute something that will actually improve their lives and not require them to come back to try again to reduce their pain. We’ve been trying to be hyper focused on reducing that variability through a number of ways.

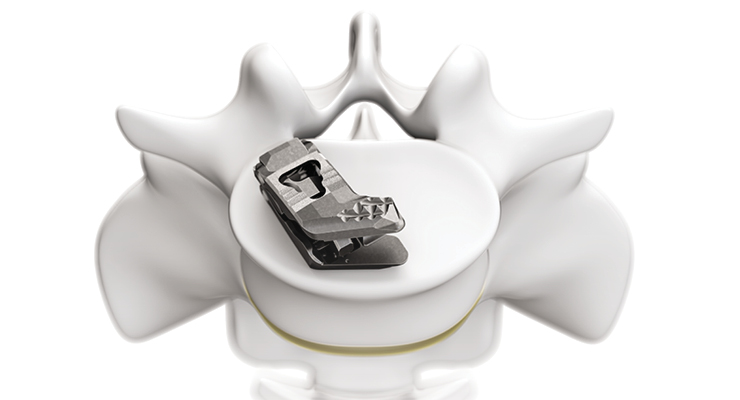

What’s exciting is that in the past at Medtronic we’ve been just an implant and instrument company, innovating around the implants and biologics used at the point of intervention. Now we’ve expanded our capabilities into enabling technologies and artificial intelligence and data to attack that same problem. We’ve taken another step in advanced material science, with surface technologies as well as biologics that increase the rate of fusion and probability of success. Also on the implant side, we look into enhancements in functional capabilities like efficient expansion of interbody cages and how that maximizes lordotic correction and proper sagittal alignment, which is a really important outcome for patients and surgeons.

Outside of the implant, we’re also attacking variability through our enabling technology platforms. That’s what's really exciting, the talk about us being more than an implant company. We’ve broadened our horizons in enabling technologies like imaging, navigation, and now robotics, that allow us to increase procedural precision and accuracy through real-time visualization and automation.

And we’ve now entered this realm of data science and data analytics with artificial intelligence, building algorithms for better clinical decisions. One element of that is customizing implants, where we have patient-specific capabilities and solutions and reduce the chance of malalignment or the need for another surgery, because the solution was created with that personalized patient anatomy and history in mind.

Ultimately all of these things come together in a very unique and differentiated ecosystem, where the components of the system talk and work with each other in an efficient and effective fashion, which makes it all the more meaningful, especially as we look to continue to lead in minimally invasive spine surgery.

Brusco: Please comment on recent Medtronic spinal technology achievements.

Weatherby: We have a more exciting and more robust pipeline than we’ve ever had. “We’ve got our swagger back” is the tagline I’ve been using. We’re pumping out products at a rate we haven’t seen in years—if not decades—and not just inorganic through acquisitions and investments like robotics with Mazor, nanotechnology with Titan Spine, or artificial intelligence with the Medicrea acquisition. Our organic innovation engine is humming in ways it hadn’t been in a long time.

We recently launched the Catalyft PL system, a new titanium expandable interbody system that has unique design features that increase the engagement of the anatomy and the implant, but also seamlessly integrates with our StealthStation navigation system and more simplified bone graft delivery system. While this provides both active expansion and precise angles for lordotic correction, there’s also the visualization and efficiency in the procedure—this ecosystem that works better together. We recently did a targeted market release this last fiscal quarter, and now we’re going to full market release and are excited to get this in more surgeons’ hands.

We also just launched the SpaceD access system in the last couple of months. This is a pedicle screw based base distraction and retraction system that’s compatible with our CD Horizon Solera Voyager minimally invasive screw system. This enables the procedure to be more efficient, offer all-in-one access for surgeons, and makes the procedure more reproducible. We’re not only innovating on the implant, but also on the tools and instrumentation that ultimately allow the surgeon to have an easier, more effective, and more efficient experience when doing these procedures.

There is also our Accelerate graft delivery system with Grafton DBF Inject. This enables more controlled and efficient bone graft material delivery into the disc space. It integrates seamlessly with the new Catalyft expandable interbody cage.

We are launching not just products, but procedural solutions where multiple technologies and products are coming together for a better outcome.

We are leading in not just implants and enabling technology, but also data science and analytics, artificial intelligence, and machine learning to improve outcomes. We recently got approval for our new UNiD rod—the patient-specific rods that came through our Medicrea acquisition, where a hub creates a surgical plan based on individual patient conditions and anatomy. Those rods are now FDA approved for use with our portfolio of minimally invasive screw systems—think of this as a personalized, pre-bent rod prior to surgery based on an artificial intelligence-driven surgical plan that allows us to reduce malalignment or the need for a second procedure. Compare this to manually bent rods not based on a pre-op plan.

The importance of it all is they’re integrated into a comprehensive solution better for the surgeon and the patient. We’re very confident this is a great example of us leading the way in minimally invasive spine surgery.

We continue to raise the bar in minimally invasive spine surgery through our commitment of driving innovation, but also expanding our minimally invasive capabilities. We’re seamlessly integrating implants, instrumentation, enabling technologies, and artificial intelligence into a single ecosystem. That helps surgeons remove variability and ultimately leads to better patient outcomes. We’re the only organization that offers this complete procedural solution with all those components.

Tools of the Trade

Contract manufacturers and service providers are very significant contributors to the spinal device industry. Spine technology OEMs can’t always handle every step of product development and manufacturing on their own, so they often enlist the assistance of specialized firms that manufacture implants, instruments, or components used by spinal device OEMs for their finished products. This partnership helps to save costs for the OEM, speed development and commercialization efforts, and allow the OEM to focus more on valuable R&D initiatives for innovative new products.

To gather insight on manufacturing implants, components, and instruments used in spine surgery, ODT spoke to the following experts in the industry:

Rodolfo Dairiki, production director at In’Tech Medical SAS, a Rang-du-Fliers, France-based contract manufacturer of orthopedic devices.

Michael Gauthier, president of Gauthier Biomedical Inc., a Grafton, Wis.-based designer and manufacturer of surgical instruments.

Brandon Gehrmann, account executive for the Americas at PHACON Inc., an Atlanta, Ga.-based provider of anatomical models that mimic human specimens.

Adam Paltzer, VP of operations at Able Medical Devices, a Gwinn, Mich.-based manufacturer of surgical systems and custom instrumentation for the spine, trauma, and cardiothoracic markets.

Rich Riddle, director of sales at rms Company, a Coon Rapids, Minn.-based manufacturer of machined implants and device components for medical device OEMs.

Jim Schultz, VP of customer solutions at ECA Medical Instruments, a Thousand Oaks, Calif.-based designer and manufacturer of single-procedure torque-limiting instruments and sterile-packed, surgery ready procedural kits.

Deborah S. Smith, director of quality and regulatory affairs at Tegra Medical’s Hernando, Miss., location. Tegra Medical is an end-to-end contract manufacturer of medical devices.

Brusco: What are the most important considerations for manufacturing spinal implants or instruments?

Rodolfo Dairiki: To successfully develop and launch a new product line, the OEM should partner with its supplier of choice early enough in the design process (i.e., prior to design freeze). This would ensure the OEM can incorporate any DFM feedback. The OEM should also take into consideration several factors:

Michael Gauthier: One of the most important considerations is the engineering expertise that goes into manufacturing spinal instruments. As a biomedical engineer, I’m biased engineering can provide value to just about anything. Our engineers are involved in every step of development, from customization and branding to balance and ergonomics for surgeons, to DFM (design for manufacturing) exercises. Equally important is a manufacturer’s ability to scale up production to meet the demands of growing orthopedic OEMs. We have made huge investments to increase capacity and vertically integrate our operations. The ability to process an instrument from start to finish, under one roof, has paid dividends for our customers.

Brandon Gehrmann: A company that manufactures high fidelity anatomy based on real CT data. This allows companies building spinal devices and implants to use targeted specific anatomy with pathology that they can’t get from human specimens. A company targeting scoliosis in a pediatric population doesn’t have the access to pediatric anatomy for educational purposes. This is the challenge: The trend in recent years was to use extremely expensive virtual reality software. This is great for visualization, but not for the touch and feel that surgeons must possess. OEMs should focus on the impact to the patient, the surgeon’s speed, and the case’s safety and success. Getting this high level of success comes from hands-on training.

How does this happen in a virtual setting? Surgical courses aren’t new and are frequently used. These labs and courses fall short in the targeted demographics. Imagine a course for pediatric spinal fusion cases—very complex. The patient’s anatomy is much smaller than what’s offered in cadaver labs and surgical courses. There aren’t specimens available, for obvious reasons. What happens is a global lock-down, but training must continue. Hospitals don’t close, in fact they take the brunt of the load. We saw last year that universities, teaching hospitals, even OEMs benefited from at-home education from synesthetic anatomy. It’s amazing to the see the advancements of spinal technologies, from nano and fusion devices to 3D printed implants.

Adam Paltzer: Understanding the requirements, which goes beyond our customers’ specifications to include end-user and patient needs and outcomes. Many of us at Able have decades of experience designing and manufacturing spinal instruments and implants, which helps us understand and fulfill our customers’ needs.

Rich Riddle: One of the challenges is the propensity to over design and tightly tolerance implants when it is not necessary for fit or function. This adds unnecessary complexity and cost to the manufacturing process with little to no benefit to the function of the device.

Jim Schultz: Instruments must be ergonomic, clinically robust, and tailored for implant prep and fixation. They must also present measurable economic value whether used in the hospital, HOPD, or ASC setting. To achieve all three of these goals implant OEMs are rapidly moving toward technologies and fulfillment models for sterile pack, surgery ready implants as well as instrument sets. We support companies desiring to cut costs and streamline OR use and turnover with single-use instrumentation solutions optimized and tailored for the procedure—be it fracture or degeneration repair for a wide range of trauma, extremity, spine, and large joint surgeries.

Precision single-use torque limiters on power tools reduce surgeon fatigue and speed up surgeries during final tightening of pedicle screws and constructs during scoliosis cases. Sterile pack kits holding implants and instruments are OR ready to support surgeon needs for efficient and cost-effective repair of many procedures ranging from distal radius, clavicle, and fibula fractures to securing suture anchors, hammertoe implants and compression screws. These benefits, coupled with time to market and ROI advantages achieved with single-use procedure kits, is making sterile pack, surgery ready instrumentation a mainstream solution across the ortho market.

Deborah S. Smith: There are two equally important key considerations to success: fully understanding and committing to meeting customer requirements, and engaging employees in development and continuous improvement efforts to implement and maintain a solid quality system with ever-changing requirements. Over the past 20 years, we have seen the quality requirements for spine devices become increasingly more stringent. By partnering closely with customers, a CMO can build a mature, robust quality system as it learns from customers and becomes stronger. The quality system can only be as good as the people willing to make the commitment to following it; we have learned ensuring employees have made the commitment to work as a team internally and continuously partner with customers must be part of our DNA.

In contrast, intra-op imaging technology has been further developed to enable accurate 3D spinal image acquisition that can be readily used for spinal navigation. Integration of these tools can maximize procedural safety, consistency, reliability, and efficacy. As such, a trend for spinal device makers is to incorporate many enabling technologies into spinal robotic systems or spine procedures in general. Advanced planning software and navigation is expected to allow wider application and value in the near future. In the long-term, enabling technologies like augmented reality could be a component of spinal robots.

Proprio, a Seattle-based computational imaging company providing enhanced visualization systems for precision tasks, has a flagship surgical navigation system that provides surgeons with an enhanced, real-time view of anatomy. This was made possible in part by the artificial intelligence (AI) solution of computer vision, which endows machines with visual recognition that mimics human sight. With the system, surgeons can view more of the patient’s anatomy, and boost situational awareness.

Extended reality (XR) first entered surgical technology through Microsoft’s Hololens. But the computer vision behind Proprio’s augmented reality solution lets surgeons view inside the anatomy while operating in real time. Proprio’s PARADIGM system is an algorithmic, real-time, multimodal image registration device that utilizes a multi-camera system. Surgeons can access pre-op imaging, powerful magnification, virtual annotation, and collaborative feedback in their field of view using the system. The system is intuitive to use as well because this perspective shifts with the surgeon.

“At Proprio, our goal is to enhance human capability and performance in medicine,” said Samuel Browd, M.D., Ph.D., co-founder and chief medical officer of Proprio. “We combine AI, XR, and computer vision to radically shift perception and create the new way of seeing. Through intuitive design and close collaboration between physicians, designers, and engineers, Proprio gives surgeons enhanced situational awareness with the objective to deliver better clinical outcomes.”

Another recent and significant advancement in spine surgery supporting technology was the FDA nod and subsequent commercial launch of global spine tech company NuVasive’s Pulse integrated technology platform at the end of July. It entered the EU market via CE mark approval earlier in the summer.

The Pulse platform aims to boost spine surgery safety, efficiency, and reproducibility via surgeon access to multiple technologies from a condensed footprint. The company’s LessRay tech increases OR efficiency through streamlined imaging workflow, and significantly reduces radiation exposure to everyone in the room. It supports various imaging systems, including enhanced integration with Siemens’ Cios Spin 3D mobile C-arm. Navigation technology helps to improve screw placement accuracy and further minimize radiation. Neuromonitoring allows automated nerve detection for reduced variability and faster neural information interpretation.

Integrated Global Alignment (iGA) provides surgical planning and intra-op assessment tools for spinal alignment correction and restoration, and surgeons can follow up post-op to assess procedural results. Bendini patient-specific rod bending creates rods bent to implant locations. Computer-assisted bend instructions expedites manual rod manipulation. And wireless connectivity capability permits all members of the OR surgical team to connect and control the Pulse platform—from surgeon, to C-arm technologist, to support staff.

“This first-of-its-kind platform supports all spine procedure types—from open to less invasive techniques,” Massimo Calafiore, NuVasive executive VP, Global Business Units, told the press. “Pulse is one of the most versatile tools in the spine OR, and the integration of multiple technologies in one platform enhances a surgeon’s capabilities to make better, more informed clinical decisions for their patients.”

“This is the culmination of years of research and development to deliver a platform that helps improve clinical, financial, and operational outcomes,” commented NuVasive CEO J. Christopher Barry. “Like we did with XLIF, Pulse is a disruptive technology that has the ability to transform not only the trajectory of NuVasive but the future of spine care for patients.”

Medtronic’s Spine Surgery Insight

Medtronic’s arsenal of spinal technologies is impressive—enough to land the company’s division in the fifth spot among ODT’s Top 10 orthopedic device companies report this year. The firm offers solutions for balloon kyphoplasty, bone grafting, cervical arthroplasty, drug infusion systems for chronic pain and severe spasticity, electrosurgical products, high-speed surgical drills and tools, intra-op neuromonitoring, nucleus removal tools, posterior occipitocervical upper-thoracic reconstructive systems, RA systems for bone tumors, spinal cord stimulators, spine robotics, SpineLine reimbursement, surgical imaging and navigation systems, an expandable corpectomy system, tumor management, and vertebroplasty.

ODT recently had the pleasure of speaking with Carlton Weatherby, vice president and general manager of spine and biologics at Medtronic, for an inside look into what his company is doing to further innovate in spine surgery.

Sam Brusco: How is Medtronic’s technology addressing unmet clinical needs for spine surgery?

Carlton Weatherby: Ultimately spine surgery is still more art than science, and the clinical goal and objective is reducing variability in clinical outcomes to ensure patients can go in confidently into a procedure, where surgeons perform and execute something that will actually improve their lives and not require them to come back to try again to reduce their pain. We’ve been trying to be hyper focused on reducing that variability through a number of ways.

What’s exciting is that in the past at Medtronic we’ve been just an implant and instrument company, innovating around the implants and biologics used at the point of intervention. Now we’ve expanded our capabilities into enabling technologies and artificial intelligence and data to attack that same problem. We’ve taken another step in advanced material science, with surface technologies as well as biologics that increase the rate of fusion and probability of success. Also on the implant side, we look into enhancements in functional capabilities like efficient expansion of interbody cages and how that maximizes lordotic correction and proper sagittal alignment, which is a really important outcome for patients and surgeons.

Outside of the implant, we’re also attacking variability through our enabling technology platforms. That’s what's really exciting, the talk about us being more than an implant company. We’ve broadened our horizons in enabling technologies like imaging, navigation, and now robotics, that allow us to increase procedural precision and accuracy through real-time visualization and automation.

And we’ve now entered this realm of data science and data analytics with artificial intelligence, building algorithms for better clinical decisions. One element of that is customizing implants, where we have patient-specific capabilities and solutions and reduce the chance of malalignment or the need for another surgery, because the solution was created with that personalized patient anatomy and history in mind.

Ultimately all of these things come together in a very unique and differentiated ecosystem, where the components of the system talk and work with each other in an efficient and effective fashion, which makes it all the more meaningful, especially as we look to continue to lead in minimally invasive spine surgery.

Brusco: Please comment on recent Medtronic spinal technology achievements.

Weatherby: We have a more exciting and more robust pipeline than we’ve ever had. “We’ve got our swagger back” is the tagline I’ve been using. We’re pumping out products at a rate we haven’t seen in years—if not decades—and not just inorganic through acquisitions and investments like robotics with Mazor, nanotechnology with Titan Spine, or artificial intelligence with the Medicrea acquisition. Our organic innovation engine is humming in ways it hadn’t been in a long time.

We recently launched the Catalyft PL system, a new titanium expandable interbody system that has unique design features that increase the engagement of the anatomy and the implant, but also seamlessly integrates with our StealthStation navigation system and more simplified bone graft delivery system. While this provides both active expansion and precise angles for lordotic correction, there’s also the visualization and efficiency in the procedure—this ecosystem that works better together. We recently did a targeted market release this last fiscal quarter, and now we’re going to full market release and are excited to get this in more surgeons’ hands.

We also just launched the SpaceD access system in the last couple of months. This is a pedicle screw based base distraction and retraction system that’s compatible with our CD Horizon Solera Voyager minimally invasive screw system. This enables the procedure to be more efficient, offer all-in-one access for surgeons, and makes the procedure more reproducible. We’re not only innovating on the implant, but also on the tools and instrumentation that ultimately allow the surgeon to have an easier, more effective, and more efficient experience when doing these procedures.

There is also our Accelerate graft delivery system with Grafton DBF Inject. This enables more controlled and efficient bone graft material delivery into the disc space. It integrates seamlessly with the new Catalyft expandable interbody cage.

We are launching not just products, but procedural solutions where multiple technologies and products are coming together for a better outcome.

We are leading in not just implants and enabling technology, but also data science and analytics, artificial intelligence, and machine learning to improve outcomes. We recently got approval for our new UNiD rod—the patient-specific rods that came through our Medicrea acquisition, where a hub creates a surgical plan based on individual patient conditions and anatomy. Those rods are now FDA approved for use with our portfolio of minimally invasive screw systems—think of this as a personalized, pre-bent rod prior to surgery based on an artificial intelligence-driven surgical plan that allows us to reduce malalignment or the need for a second procedure. Compare this to manually bent rods not based on a pre-op plan.

The importance of it all is they’re integrated into a comprehensive solution better for the surgeon and the patient. We’re very confident this is a great example of us leading the way in minimally invasive spine surgery.

We continue to raise the bar in minimally invasive spine surgery through our commitment of driving innovation, but also expanding our minimally invasive capabilities. We’re seamlessly integrating implants, instrumentation, enabling technologies, and artificial intelligence into a single ecosystem. That helps surgeons remove variability and ultimately leads to better patient outcomes. We’re the only organization that offers this complete procedural solution with all those components.

Tools of the Trade

Contract manufacturers and service providers are very significant contributors to the spinal device industry. Spine technology OEMs can’t always handle every step of product development and manufacturing on their own, so they often enlist the assistance of specialized firms that manufacture implants, instruments, or components used by spinal device OEMs for their finished products. This partnership helps to save costs for the OEM, speed development and commercialization efforts, and allow the OEM to focus more on valuable R&D initiatives for innovative new products.

To gather insight on manufacturing implants, components, and instruments used in spine surgery, ODT spoke to the following experts in the industry:

Rodolfo Dairiki, production director at In’Tech Medical SAS, a Rang-du-Fliers, France-based contract manufacturer of orthopedic devices.

Michael Gauthier, president of Gauthier Biomedical Inc., a Grafton, Wis.-based designer and manufacturer of surgical instruments.

Brandon Gehrmann, account executive for the Americas at PHACON Inc., an Atlanta, Ga.-based provider of anatomical models that mimic human specimens.

Adam Paltzer, VP of operations at Able Medical Devices, a Gwinn, Mich.-based manufacturer of surgical systems and custom instrumentation for the spine, trauma, and cardiothoracic markets.

Rich Riddle, director of sales at rms Company, a Coon Rapids, Minn.-based manufacturer of machined implants and device components for medical device OEMs.

Jim Schultz, VP of customer solutions at ECA Medical Instruments, a Thousand Oaks, Calif.-based designer and manufacturer of single-procedure torque-limiting instruments and sterile-packed, surgery ready procedural kits.

Deborah S. Smith, director of quality and regulatory affairs at Tegra Medical’s Hernando, Miss., location. Tegra Medical is an end-to-end contract manufacturer of medical devices.

Brusco: What are the most important considerations for manufacturing spinal implants or instruments?

Rodolfo Dairiki: To successfully develop and launch a new product line, the OEM should partner with its supplier of choice early enough in the design process (i.e., prior to design freeze). This would ensure the OEM can incorporate any DFM feedback. The OEM should also take into consideration several factors:

- Machining capabilities (what type of CNC-equipment may be required? 5-axis milling? EDM? Grinding?)

- Level of supplier’s quality system (will the supplier be able to support me with FDA and MDR required process validations?)

- Prototyping capabilities and scalability (can the supplier support me with verified and validated prototypes and scale up as the product is introduced and distributed?)

- Finally, the OEM would have everything to gain by identifying a one-stop-shop partner capable of answering its various needs, from concept development to kitting and delivery.

Michael Gauthier: One of the most important considerations is the engineering expertise that goes into manufacturing spinal instruments. As a biomedical engineer, I’m biased engineering can provide value to just about anything. Our engineers are involved in every step of development, from customization and branding to balance and ergonomics for surgeons, to DFM (design for manufacturing) exercises. Equally important is a manufacturer’s ability to scale up production to meet the demands of growing orthopedic OEMs. We have made huge investments to increase capacity and vertically integrate our operations. The ability to process an instrument from start to finish, under one roof, has paid dividends for our customers.

Brandon Gehrmann: A company that manufactures high fidelity anatomy based on real CT data. This allows companies building spinal devices and implants to use targeted specific anatomy with pathology that they can’t get from human specimens. A company targeting scoliosis in a pediatric population doesn’t have the access to pediatric anatomy for educational purposes. This is the challenge: The trend in recent years was to use extremely expensive virtual reality software. This is great for visualization, but not for the touch and feel that surgeons must possess. OEMs should focus on the impact to the patient, the surgeon’s speed, and the case’s safety and success. Getting this high level of success comes from hands-on training.

How does this happen in a virtual setting? Surgical courses aren’t new and are frequently used. These labs and courses fall short in the targeted demographics. Imagine a course for pediatric spinal fusion cases—very complex. The patient’s anatomy is much smaller than what’s offered in cadaver labs and surgical courses. There aren’t specimens available, for obvious reasons. What happens is a global lock-down, but training must continue. Hospitals don’t close, in fact they take the brunt of the load. We saw last year that universities, teaching hospitals, even OEMs benefited from at-home education from synesthetic anatomy. It’s amazing to the see the advancements of spinal technologies, from nano and fusion devices to 3D printed implants.

Adam Paltzer: Understanding the requirements, which goes beyond our customers’ specifications to include end-user and patient needs and outcomes. Many of us at Able have decades of experience designing and manufacturing spinal instruments and implants, which helps us understand and fulfill our customers’ needs.

Rich Riddle: One of the challenges is the propensity to over design and tightly tolerance implants when it is not necessary for fit or function. This adds unnecessary complexity and cost to the manufacturing process with little to no benefit to the function of the device.

Jim Schultz: Instruments must be ergonomic, clinically robust, and tailored for implant prep and fixation. They must also present measurable economic value whether used in the hospital, HOPD, or ASC setting. To achieve all three of these goals implant OEMs are rapidly moving toward technologies and fulfillment models for sterile pack, surgery ready implants as well as instrument sets. We support companies desiring to cut costs and streamline OR use and turnover with single-use instrumentation solutions optimized and tailored for the procedure—be it fracture or degeneration repair for a wide range of trauma, extremity, spine, and large joint surgeries.

Precision single-use torque limiters on power tools reduce surgeon fatigue and speed up surgeries during final tightening of pedicle screws and constructs during scoliosis cases. Sterile pack kits holding implants and instruments are OR ready to support surgeon needs for efficient and cost-effective repair of many procedures ranging from distal radius, clavicle, and fibula fractures to securing suture anchors, hammertoe implants and compression screws. These benefits, coupled with time to market and ROI advantages achieved with single-use procedure kits, is making sterile pack, surgery ready instrumentation a mainstream solution across the ortho market.

Deborah S. Smith: There are two equally important key considerations to success: fully understanding and committing to meeting customer requirements, and engaging employees in development and continuous improvement efforts to implement and maintain a solid quality system with ever-changing requirements. Over the past 20 years, we have seen the quality requirements for spine devices become increasingly more stringent. By partnering closely with customers, a CMO can build a mature, robust quality system as it learns from customers and becomes stronger. The quality system can only be as good as the people willing to make the commitment to following it; we have learned ensuring employees have made the commitment to work as a team internally and continuously partner with customers must be part of our DNA.