When entering into a relationship with a supplier who will help support the development and manufacturing of an orthopedic implant, it is critical to make the right decision to ensure the correct balance between high quality of service, cost-efficient product-to-service ratio, and fast time to market. Getting that choice right, however, isn’t easy. It’s crucial to find a well-established partner who has broad capabilities and brings together the core competencies of R&D, product design, regulatory affairs, and manufacturing—all under one roof.

Francesco Bucciotti, managing director USA at Lincotek Medical, shares his thoughts on this critical topic and also reflects on how COVID-19 helped illustrate the vulnerability of many companies’ supply chains. The pandemic brought the importance of working with quality partners to the forefront. It is critical to find a company with a fully-integrated offering and multiple locations around the globe to support shifting manufacturing needs, reduce risks and complexity, and consolidate the supply base. Finally, Bucciotti also highlights the most important factors to consider when selecting a supplier given the revelations that emerged as most critical.

Sean Fenske: What is Lincotek Medical and what do you do?

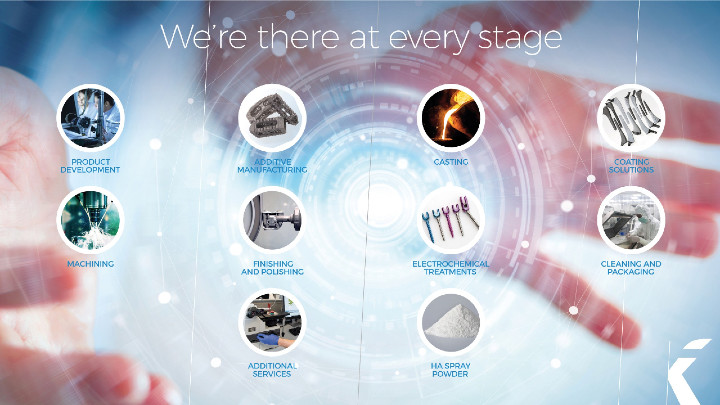

Our new strategy is disruptive and allows us to provide true “Concept to Launch” support to orthopedic OEMs, assisting customers during all stages of their development and manufacturing journey, from device conception and manufacturing through to finishing and polishing, and eventual packaging and sterilization.

We can provide support for a single development or manufacturing step, or offer a fully-integrated service. We believe in strategic relationships, acting as a company's primary development and manufacturing partner, or acting as a key component of an existing supply chain. Further, quality and regulatory compliance is a core element: all of our manufacturing sites are ISO 13485 certified, with most FDA registered. Quality is the cornerstone of our services and Lincotek Medical is fully committed to the journey.

Fenske: What are your offerings and capabilities within the U.S. specifically?

Bucciotti: In 2010, Lincotek Medical set up a presence in the U.S., starting the operation with Surface Dynamics in Memphis (TN). The facility offers the most innovative plasma spray coatings and additive manufacturing services tailored to suit U.S. market requirements.

In mid-2019, we strengthened our development engineering and manufacturing expertise with the acquisition of former CoorsTek Medical, with locations in Portland (OR), Logan (UT), and Dayton (OH). Combined with our already existing market-leading coating and additive manufacturing capabilities, the move enabled us to provide our OEM customers with a unique and comprehensive portfolio of services wherever they may be based.

Lincotek Medical's facility in Dayton, Ohio.

The medical device markets served by Lincotek Medical are spine, reconstruction, sports medicine and trauma, and extremities. In all of these markets, we have deep experience with product development, prototyping, product launch, and volume production.

We are a knowledge- and data-driven company. Almost all processes are automated, inputs monitored and controlled, and decisions are based on the trends of input and outputs. Further, we always invest in our people to guarantee the best possible solution for customers and have spent years training and cultivating market experts, which proves important when customers face the challenges of regulatory hurdles or have requirements related to custom patient-specific parts.

Our Product Development team leads the industry by partnering with customers in ways that best support their objectives. For example, we work with OEMs to help them bring products to the market, and—through them—with key opinion-leading surgeons to develop innovative, potentially disruptive solutions. Our flexible engagement model ranges from contract development engineering to technology licensing. We have over 100 years of medical device regulatory experience, with over 175 510(k)s filed, supported by our onsite internal testing and validation lab. Our dedicated Prototype Shop offers fast turnaround of machined parts for lab evaluation, and 3D-printed prototypes. During transition from MDD to MDR, our European design team helped many OEMs make the transition and launch new products as well.

Product development: Accelerating the journey from design concept to product launch.

We pride ourselves on the comprehensive manufacturing services solution we’re able to offer our customers. That means a complete additive manufacturing service offer, from powder to finished product, managing the complete supply chain for serial volume production, yielding high volume. We have more than 25 machines in production, produced over 110,000 parts in 2020, and have best-in-class scrap rates and quality. Overall equipment efficiency (OEE) is far above 90%. And that’s complemented by our precision machining capability for finished devices.

An additively manufactured finished tibial plate.

An investment casting mold a few minutes after it had been cast.

We also offer full-service precision machining capability of implants and instruments. We provide design for manufacture, process development and validation, and product launch through volume manufacturing. Our largest markets for precision machining are spine, joint reconstruction, trauma, extremities, and sports med across both implants and instruments.

A Lincotek Medical employee cleaning and packaging coated stems in a controlled environment.

By providing all of these services within Lincotek Medical, we deliver our customers speed to market and speed to quality. We can launch and scale globally, and are ready to invest to meet our customer's specific needs. Our customer centric management approach is data and expectation driven. We make complex development, launch, and production projects simple with our centralized program management approach. Collaboration is encouraged, with formal communication tools to ensure strategic and tactical alignment. Long term, meaningful relationships with our customer are Lincotek Medical's primary objective.

Fenske: When a customer approaches you for a project, what are your first steps to help ensure success?

Bucciotti: We keep an intense focus on innovation and the flexibility of meeting a client’s requirements. That’s why we always run trials and simulations to determine the best method to achieve results. To elaborate, using additive manufacturing as an example, a customer approached Lincotek Medical to make hip stems. Our team took this as a challenge, but with an approach to ensure that if there was residual porosity, its presence would be minimal in certain high-risk areas.

Another completely different example is when a customer approached Lincotek Medical to investigate whether thermal spray of a certain kind of mineralized phosphate would be feasible. After discussions with the customer, a better solution-based electrochemical method was identified and is being developed to address their needs. Naturally, the customer is very excited, as this approach allows them to differentiate their product from other OEMs addressing similar clinical challenges, but also leads them to move into 3D-printed Ti6AlV implants with this special mineralized phosphate via electrochemical technique.

Fenske: What other types of challenges do customers present to you and how do you handle them?

Bucciotti: It is important to realize the medical device market has been changing quickly. To keep pace, our customers must outperform the market and, as such, they expect the same from their outsource partners. Due to increased regulatory complexity, launching a new product today basically takes much longer and costs considerably more than it used to while selling prices are steadily shrinking.

As a result, OEMs look for reduced costs, high quality, and faster timelines that meet the expectations and demands of the entire healthcare community. As they explore new marketplaces, innovation and development gets compressed into very narrow timelines.

Tracing the roots of our organization back for many years, we have learned to adapt and be flexible to meet these changing needs of the market. We need to accommodate faster lead times and high quality in a cost-efficient service, helping OEMs get their product to market efficiently while staying focused on things that really enable them to stay competitive in the market. And, of course, we must meet every region’s regulatory requirements.

Lincotek Medical offers a wide range of fully integrated services.

With these goals in mind, we brought together the core competencies of R&D, manufacturing, and regulatory affairs in order to offer the opportunity to our clients to tap into a portfolio of solutions. We can drive any new development through all the milestones, complementing the client’s organization, streamlining the supply chain in order to minimize production costs. That basically means we can either help you developing a new product or have a product developed for you, registered for you, and manufactured for you.

Fenske: Given what was revealed during the pandemic, how important is an integrated supply chain for orthopedic device manufacturers?

Bucciotti: One area facing the most challenges and disruption during the pandemic has been the supply chain. COVID-19 disrupted everything from supply and demand to shipping and workplace capacity. Manufacturers were grappling daily with managing short- and long-term demand, while facing severe shortages of critical supplies. The biggest challenges facing supply chains during the pandemic were continuity of supply, regulatory pressure, risk management, and visibility.

COVID-19 illustrated that many companies are not fully aware of the complexity and vulnerability of their supply chain to global shocks. Many in the industry have poor visibility into the entire flow and don’t have sufficient alternative suppliers. With the need for increased visibility, we are already seeing a shift from linear supply chains to more integrated solutions to mitigate future risks.

The current supply base in the orthopedic field is large and very fragmented. Orthopedic OEMs continue to face pressure over pricing, as well as quality and regulation. Not only that, but the pressure is on to provide competitive service and fast delivery. So, working with a full-service contract manufacturer helps OEMs to reduce risks and complexity and consolidate their supply base, concentrating on things that really enable them to stay competitive in the market.

Fenske: When building a supplier network, what are the most important factors to consider in identifying a partner?

Bucciotti: Procurement teams at OEMs are striving hard to cultivate and retain contract manufacturers who can deliver on a promise in a sustainable way. They want a partner to help them reach their objective of revenue and profit growth, while delivering the best devices to its surgeon community.

I can illustrate the most important factors through Lincotek’s three main pillars of our business model. So, here’s what sets Lincotek apart:

- Our partnership model, based upon a collaborative approach at each level of the working relationship with customers. It’s much more than a classic customer-supplier relationship where customers look for their desired specification at the lowest price; we offer a truly integrated supply chain solution, developed together with our customers.

- Our flexibility, being able to guarantee the attention and the flexibility typical of a small company, but with the resources of a big business.

- Our extensive and deep knowledge of the technology and mastering of the process and associated quality requirements at all steps of the supply or what we call “tribal knowledge” or “savoir faire.” We know how to undertake the process, but it’s not necessarily something written down; it’s something continued by our people. It’s the perfect union of two fundamental elements—the skills and expertise handed down within the company year after year, and the deep scientific/technological knowledge built up through years of research and development.

It’s also important to find a reliable partner that gives confidence and reassurance to plan for the future—a business that is able to industrialize new solutions when needed and consequently invest to support the customer’s growth.

A medical device OEM needs to seek out a partner who can offer similar capabilities and expertise so they can be certain the partnership will be a success.

I encourage those OEMs to come meet us in San Diego at AAOS (Booth #2925) to discuss how we can help them on their next project.

Learn more about Lincotek Medical here >>>>>