While “standing out” from competitors is quite important to an orthopedic device manufacturer’s marketing team, many more advantages can be realized in the effort to differentiate a company’s product used for a surgical procedure. Whether a tray system for a complete procedure or a single instrument’s grip, using a custom approach can make a surgeon notice.

There are numerous ways in which a company can present itself as a unique solution for orthopedic surgeons, and leveraging modularity and personalization options through a supply partner are near the top of the list. The right company can offer a variety of options that will reinforce the company’s identity, while also truly impacting the procedure in a clinically beneficial way.

To offer a much deeper dive into the benefits of customization, Francois Samson, Sr. Manager Strategic Marketing at Intech, took time to respond to several questions in the following Q&A. He shares insights on the company’s approach to tray design and the reasons customers are requesting certain aspects for their newest products.

Sean Fenske: Why is it important for device firms to “stand out” in the OR? What advantages does it provide at the point of care?

Francois Samson: With an increasing demand for personalized and effective medical solutions, orthopedic medical device companies must find solutions to “stand out” in the OR. One approach that has proven to be a game-changer is the combination of customization and modularity. Customization involves tailoring a device or system to a specific implant or approach. By building-in customization into their designs, medical device companies can create products that are not only functional but also aesthetically appealing and user-friendly. This not only enhances the surgeon’s experience but also helps the company stand out in the operation room while positioning itself as a leader in medical innovation.

Custom trays are designed to be versatile and adaptable, allowing them to be used for multiple procedures while supplying the specific size instruments or implants required for a particular procedure.

Fenske: What are some of the primary customization options that can be made to an off-the-shelf tray?

Samson: Our Inbox off-the-shelf design for trays can be endlessly customized to fit a customer’s needs. Some of the primary customization options that are commonly available include:

- Tray material—Stainless steel, aluminium, Radel; different materials offer different benefits such as durability, heat resistance, and lightweight.

- Lid material—Radel (PPSU) for translucency, stainless steel or aluminium

- Multiple sizes—½ DIN, 2/3 DIN, full DIN, and 1 or 2 levels; these different sizes allow for the tray to be tailored to the specific needs of the application.

- Color combination—Custom colors can be chosen to match branding or aesthetic preferences.

- Add logo or custom branding—Thanks to deep image anodization, trays can branded in unique ways to stand out in the OR.

- Silk screening or laser engraving—These are great options for instrument placement identification.

- Perforation—Perforation geometry can also be customized upon request with up to 70% perforation rate thanks to our high-perforated Wash’Inbox.

Fenske: What benefits beyond branding or differentiation do custom options enable (e.g., clinical, procedural, etc.)?

Samson: There are several benefits that can be achieved.

- Improved efficiency: Custom trays can be designed to suit specific clinical and procedural requirements, which can streamline the process and reduce the time and effort required for preparing and assembling the necessary instruments and supplies. This can result in improved efficiency and productivity in the clinical setting.

- Reduced risk of errors: Custom trays can also reduce the risk of errors and complications during procedures by ensuring the necessary instruments and supplies are readily available and properly organized. This can help to minimize the risk of mistakes and improve patient safety.

- Better patient outcomes: Custom trays can be designed to include the specific instruments and supplies required for a particular procedure or clinical application. This can help to ensure patients receive the best possible care and achieve better outcomes.

- Cost savings: Custom trays can be optimized to include only the necessary instruments and supplies, which can help to reduce waste, provide faster SPD turnaround, and lower costs for healthcare providers.

- Increased flexibility: Custom trays can be designed to be versatile and adaptable, allowing them to be used for a variety of clinical applications and procedures. This can provide greater flexibility and convenience for healthcare providers and improve patient care.

With proven designs, Intech can fast-track your next launch from design to manufacturing.

Samson: Indeed, customization does have an impact on cleaning and sterilization of medical cases and trays. When designing custom trays, it's important to consider factors such as the materials used, the size and shape of the tray, and the layout of instruments that may affect air flow, which is a critical component as part of cleaning and sterilization. Our designers understand these challenges and know where these boundaries lie.

Certain aspects of the tray or handles may need to remain a certain style or size to ensure effective cleaning and sterilization. For example, all trays should be designed to be easy to clean and sterilize, with no blind holes or other areas that could trap tissue or bacteria. The size of the tray should also be considered, as larger trays may be more difficult to sterilize than smaller ones. That said, standard DIN, 2/3 DIN and 1/2 DIN formats are available as part of our Inbox range of solutions that are compatible with standard containers, typically used at healthcare providers.

The materials used in custom tray and instruments will inevitably impact its cleaning and sterilization. Some materials may be more resistant to high temperatures or certain types of disinfectants than others. The most durable material, both from a transport and sterilization standpoint, is stainless steel but, due to weight considerations and/or branding needs, an aluminum tray may better address specific needs.

Overall, customization of medical cases and trays can offer several benefits, but it's important to carefully consider the impact on cleaning and sterilization to ensure patient safety is not compromised.

Fenske: As both users of trays and the device firms providing them look to reduce the number of trays needed for a procedure, can customization help with this effort?

Samson: Yes, customization can help in reducing the number of trays needed for a procedure. By designing custom trays optimized for a specific procedure, healthcare providers can include only the necessary instruments and supplies, reducing the need for multiple trays.

Custom trays are also designed to be versatile and adaptable, allowing them to be used for multiple procedures while supplying the specific size instruments or implants required for a particular procedure. This provides healthcare providers with greater flexibility and convenience by eliminating the need for multiple trays, thus reducing waste and lowering costs.

Brand off-the-shelf designs to build modularity into your systems and stand-out into the O.R.

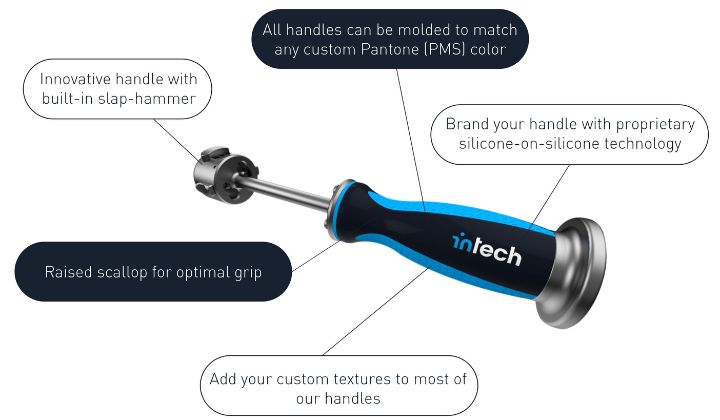

Furthermore, device firms can leverage modularity by building it into their instruments’ designs. As an example, a quick-connect handle can be used interchangeably with a variety of instruments or implants, and some of our latest designs include a built-in slap-hammer, which may be used to remove a trial or for revision surgeries.

Fenske: Can you share some of the unexpected benefits you’ve heard of due to customization? Or have you received feedback from surgeons and staff on aspects they truly appreciated?

Samson: I can think of several.

- Turnkey designs with a regulatory edge: Don’t reinvent the wheel and leverage skilled designers that will assist with anything from tray layout to instrument customization, leveraging our longstanding expertise with tried-and-tested design solutions tailored to meet custom requirements.

- Reduced lead-times: Leveraging turnkey designs will help considerably reduce lead times.

- Optimized costs: Design experts can help you leverage unique designs that are standardized while allowing for modularity, which can help you in the long run by reducing costs associated with the reconfiguration.

Intech is committed to delivering medical devices that better patients' lives.

Samson: Customization is an integral part of the future of orthopedics, as it can be applied to a wide range of products, from trays to overmolded handles. The only limit becomes one's imagination, and Intech has the expertise and knowledge to make it happen.

By offering patient-driven solutions, orthopedic device manufacturers can cater to the specific needs of their surgeons by enhancing the surgical technique and flow of the operations relaying on products they know were designed to streamline surgery steps.

As such, no matter their size, device firms should not shy away from leveraging the power of customization and work toward delivering innovative and tailored products that better people's lives. Together, we tech care.

Click here to learn more about Intech >>>>>