Automated solutions seem to have been slower within the medical device space than other industries. The use of human labor to help ensure quality has been in place for some time. However, automated solutions have continued to improve and have achieved a level that can exceed the capabilities of human labor. As such, having an automated inspection solution for medical device manufacturing may be preferable.

While human workers can be highly skilled in the task for which they are trained, there are downsides that cannot be overcome. Aspects like human bias and fatigue are simply unable to be filtered out from a human worker. On the other hand, an automated inspection solution does not suffer from these weaknesses.

To help provide further insights on the benefits of automated inspection for medical device manufacturing, Luke Bastiansen, Quality Manager—Orthopedics, and Nick Loxtercamp, Engineering Manager—Orthopedics, at rms, a Cretex Medical company responded to a number of questions in the following Q&A. They explain in greater detail the advantages of having an automated inspection system.

Sean Fenske: When it comes to inspection, why can the “human element” be problematic?

Luke Bastiansen: One thing I’ve learned from my time in quality and manufacturing is 100% manual inspection is never truly 100% effective. There are many reasons for this, but the primary causes I consider problematic are subjectivity of the criteria, attention span or fatigue of the inspector, and, perhaps most common, simple human error. Let’s face it, regardless of the task and no matter how much skill or training someone has, we as humans are prone to making errors, whether it’s due to distractions, lapses in concentration, or simply just an oversight. Unfortunately, these innocent errors can have very serious downstream consequences in the medical device industry and may even compromise patient safety.

Fenske: What advantages does automation bring that help to improve quality?

Optical inspection system that performs 100% verification of part geometry and part count.

In addition to the increased consistency and reduced human error, the inclusion of automated inspection also provides production efficiencies. In our orthopedics business unit, there are many labor-intensive inspections that can be completed with automated processes, creating more consistent throughput, and allowing resources to be allocated to other value-added tasks. While the up-front investment is certainly not something to be overlooked, the long-term cost savings make it simple to justify.

Fenske: Can you provide some real-world examples of improvements in inspection with the implementation of automation?

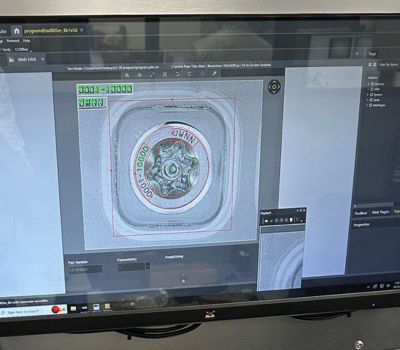

This optical character recognition (OCR) vision system checks for laser mark content, legibility, and presence, as well as drive feature presence and part count.

Since implementation, we have seen a drastic decrease in escapes related to human error. However, what these systems accomplish is far more than acting as a safety net for catching non-conformances. Our automated inspection systems provide an immediate feedback loop to our operation, providing us the opportunity for investigation and corrective action in real time. Access to this information in such close proximity and timing to the events in question has been invaluable to continuous improvement of our processes and the robustness of our operation.

Fenske: Do you face concerns from customers when you explain your use of automation for inspection?

Automated robot programmed for laser marking with an integrated vertical camera to verify drive feature presence prior to marking.

Fenske: What additional benefits are realized from the use of automation in inspection outside of quality?

Automated packaging with the ability to 100% verify part size, geometry, and count.

- Safety: Adding automation can improve the health and safety of workers by removing them from situations that could pose potential risk.

- Increased Efficiency: Automation significantly reduces inspection time compared to manual methods. No fatigue and the systems can work around the clock, which leads to quicker results and increased throughput.

- Data Collection and Analysis: Automation enables the collection of large volumes of data during inspections. The data can then be used for trend analysis and process optimization. Which helps provide valuable insight for continuous improvement.

- Faster Reporting: Automated inspection systems generate inspection reports quickly. This would allow for rapid decision making and faster corrective actions, if needed.

- Remote Monitoring: Several automated inspection systems can be monitored and controlled remotely. This allows real-time data to be monitored from any location.

- 24/7 Operation: Automated systems can operate continuously, allowing for inspections to be performed during non-working hours. This maximizes the utilization of equipment and facilities.

These benefits make automation a valuable asset in the manufacturing industry.

Fenske: Do you have any additional comments you’d like to share based on any of the topics we discussed or something you’d like to tell orthopedic device manufacturers?

Loxtercamp: As we look to the future, Cretex Medical and rms Company are dedicated to integrating automation into our manufacturing processes to drive ongoing improvement. Beyond the clear enhancements in product quality, manufacturing, and inspection, automation brings an array of benefits to our operations.

Our dedication to safety, employee growth, and staying at the forefront of innovation guarantees automation will remain a pivotal element of our competitive edge, serving as an integral component of our strategy for continuous improvement and our commitment to harness all its benefits.

Click here to learn more about rms, a Cretex Medical company >>>>>