Dave Neal, President and Founder of STAT Design11.21.19

Molybdenum-Rhenium is a new biomaterial to the orthopedic market that is exciting because of its biocompatibility, MRI and CT compatibility, and corrosion resistance. Its combination of high tensile strength and ductility allows implanted devices to be designed with a low profile. It has excellent osteo-integration properties and very low levels of ion release.

Molybdenum-Rhenium offers superior mechanical strength properties over other approved biomaterials, such as cobalt-chrome, titanium, and stainless steel. It also uses a lot less metal to achieve the same strength and durability and is two to three times stronger and four times more durable than cobalt-chrome or titanium.

By offering superior mechanical strength properties, these implantable medical devices can be made thinner, providing a low profile. Additionally, devices made from this material, can benefit from being implanted minimally invasively which may lead to improved clinical outcomes, by reducing soft tissue disruption.

History

Rhenium was discovered in 1925 and is the last stable non-radioactive inert element discovered. Molybdenum-Rhenium has its beginnings in aerospace and nuclear applications where its high strength and fatigue resistance has overcome many of the limitations of traditional materials.

Current applications

Having been used in implantable medical devices such as cardiac stents, tissue supporting scaffolds, dental posts, and implants, Molybdenum-Rhenium is now finding its way into the orthopedic market. Such applications include orthopedic reconstruction, spinal fixation, cranial reconstruction, and upper and lower extremity fixation.

MiRus recently received the first 510(k) approval for its Europa Pedicle Screw System utilizing their proprietary Molybdenum-Rhenium alloy material, “MoRe”. The FDA requires a rigorous level of scientific investigation to establish the safety and effectiveness of an implant utilizing a new biomaterial. MiRus was successfully able to put together compelling evidence to obtain FDA approval of the Molybdenum-Rhenium alloy medical device.

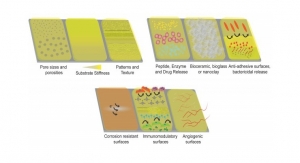

MiRus was able to characterize the hydrophilic properties through contact angle comparisons andMoRe was found to have nearly twice the hydrophilicity (CA 37°±3°) compared to Titanium (CA 58°±3°), one of the key factors in tissue response in regards to cell adhesion, migration, and replication.

A bone implantation study, based on ISO 10993: Part 6: Tests for Local Effects after Implantation, demonstrated continued bone maturation over time for both MoRe and Titanium implant sites with similar osteoconduction and bone remodeling histology of the cortical and medullary bone at 4, 13 and 26 weeks. Pre-osteoblast cell seeding was found to be equivalent between MoRe and Titanium alloy (10,000 cells/cm2).

A biofilm formation study was conducted to quantify attachment and biofilm development of S. aureus bacteria upon MoRe alloy in comparison to CoCr alloy in a well-controlled, reproducible, ex vivo laboratory experiment. The biofilm study found that S. aureus better colonized cobalt chrome alloy in comparison to MoRe (p = 0.009).

Challenges

A challenge faced with this material is its high cost. As the material gains widespread acceptance, the material cost may come down. Medicare reimbursement is an issue that has to be addressed. It’s a hard sell to offer a medical device with a high material cost, when there are alternatives available at a fraction of the cost and with a proven clinical history.

Future

Due to material limitations in foot and ankle surgery, Molybdenum-Rhenium holds promise in developing improved devices. These implants can offer improved fatigue strength and ductility, while providing the needed tensile strength. Titanium, the most commonly used alloy for foot and ankle implants, has limited strength and is notch-sensitive so repetitive stress leads to fatigue failure of implants and limits design options. Many times it can become a race against time between complete bone healing and titanium implant failure.

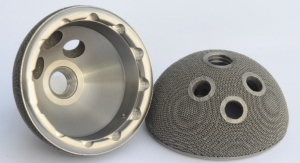

As Molybdenum-Rhenium is in powder form, could it lend itself towards additive manufacturing? As it becomes more widely used, will material cost come down? It will be interesting to see what the future holds for this promising new biomaterial offering superior cell growth, osseointegration and, biofilm resistance in the orthopedic device space.

Dave Neal, president and founder of STAT Design, is a Morris Plains, NJ-based designer and developer of orthopedic implants and instruments.

Molybdenum-Rhenium offers superior mechanical strength properties over other approved biomaterials, such as cobalt-chrome, titanium, and stainless steel. It also uses a lot less metal to achieve the same strength and durability and is two to three times stronger and four times more durable than cobalt-chrome or titanium.

By offering superior mechanical strength properties, these implantable medical devices can be made thinner, providing a low profile. Additionally, devices made from this material, can benefit from being implanted minimally invasively which may lead to improved clinical outcomes, by reducing soft tissue disruption.

History

Rhenium was discovered in 1925 and is the last stable non-radioactive inert element discovered. Molybdenum-Rhenium has its beginnings in aerospace and nuclear applications where its high strength and fatigue resistance has overcome many of the limitations of traditional materials.

Current applications

Having been used in implantable medical devices such as cardiac stents, tissue supporting scaffolds, dental posts, and implants, Molybdenum-Rhenium is now finding its way into the orthopedic market. Such applications include orthopedic reconstruction, spinal fixation, cranial reconstruction, and upper and lower extremity fixation.

MiRus recently received the first 510(k) approval for its Europa Pedicle Screw System utilizing their proprietary Molybdenum-Rhenium alloy material, “MoRe”. The FDA requires a rigorous level of scientific investigation to establish the safety and effectiveness of an implant utilizing a new biomaterial. MiRus was successfully able to put together compelling evidence to obtain FDA approval of the Molybdenum-Rhenium alloy medical device.

MiRus was able to characterize the hydrophilic properties through contact angle comparisons andMoRe was found to have nearly twice the hydrophilicity (CA 37°±3°) compared to Titanium (CA 58°±3°), one of the key factors in tissue response in regards to cell adhesion, migration, and replication.

A bone implantation study, based on ISO 10993: Part 6: Tests for Local Effects after Implantation, demonstrated continued bone maturation over time for both MoRe and Titanium implant sites with similar osteoconduction and bone remodeling histology of the cortical and medullary bone at 4, 13 and 26 weeks. Pre-osteoblast cell seeding was found to be equivalent between MoRe and Titanium alloy (10,000 cells/cm2).

A biofilm formation study was conducted to quantify attachment and biofilm development of S. aureus bacteria upon MoRe alloy in comparison to CoCr alloy in a well-controlled, reproducible, ex vivo laboratory experiment. The biofilm study found that S. aureus better colonized cobalt chrome alloy in comparison to MoRe (p = 0.009).

Challenges

A challenge faced with this material is its high cost. As the material gains widespread acceptance, the material cost may come down. Medicare reimbursement is an issue that has to be addressed. It’s a hard sell to offer a medical device with a high material cost, when there are alternatives available at a fraction of the cost and with a proven clinical history.

Future

Due to material limitations in foot and ankle surgery, Molybdenum-Rhenium holds promise in developing improved devices. These implants can offer improved fatigue strength and ductility, while providing the needed tensile strength. Titanium, the most commonly used alloy for foot and ankle implants, has limited strength and is notch-sensitive so repetitive stress leads to fatigue failure of implants and limits design options. Many times it can become a race against time between complete bone healing and titanium implant failure.

As Molybdenum-Rhenium is in powder form, could it lend itself towards additive manufacturing? As it becomes more widely used, will material cost come down? It will be interesting to see what the future holds for this promising new biomaterial offering superior cell growth, osseointegration and, biofilm resistance in the orthopedic device space.

Dave Neal, president and founder of STAT Design, is a Morris Plains, NJ-based designer and developer of orthopedic implants and instruments.