Mark Crawford, Contributing Writer12.02.19

Matching the right material to the right device to the right procedure is a key element in the development of any orthopedic implant, product, or instrument—and the abundance of materials to choose from continues to expand.

Material science is rapidly evolving to meet the needs of disruptive new manufacturing technologies such as additive manufacturing (AM) and 3D printing (3DP). Advanced injection molding can now process a wider range of polymers and even metals for key product applications. New or enhanced materials give engineers more options for creative orthopedic device designs, higher functionality, and improved patient outcomes.

Material science innovations include advanced resorbable materials, antimicrobial coatings, biodegradable metals, and bioprinting of live cells. New metalworking processes can increase the strength of standard materials by refining microstructural design. AM/3DP processes and materials allow engineers and designers to think “outside the box” and create highly functional products that cannot be made any other way.

Despite these exciting advances, orthopedic OEMs tend to remain very conservative when it comes to choosing materials for their implants and instrumentation. Adoption of new materials tends to only happen when a new design requires some level of functionality that well-tested, FDA-approved legacy materials simply cannot offer.

That said, OEMs must embrace new materials to stay on the cutting edge of technology, remain competitive, and gain market share. As demand increases for smaller, more complex, and more functional devices with highly-specific engineered material properties, medical device manufacturers (MDMs) must keep up with the latest advances in material science, such as new metal alloys, polymer/metal hybrids, bioabsorbable polymers, biocomposite polymers/ceramics, and bioprinting. Even with all these material options to consider, new materials with unique properties continue to be announced on a regular basis, especially for AM/3D printing.

To better understand the factors driving material trends in the orthopedic industry, Orthopedic Design and Technology (ODT) spoke with six industry experts who shared their insights regarding how materials are used in the design and manufacture of orthopedic products. These experts are:

Mark Crawford: What is the overall state of materials/materials science in the orthopedic device market today?

Bing Carbone: We continue to see usage of traditional medical plastics materials, but advanced materials are now ready for the market, or will be forthcoming. Materials like polyetheretherketone (PEEK), polyphenylsulfone, (PPSU), poly(methyl methacrylate) (PMMA), medical-grade acetal co-polymers, and heat-stabilized polypropylenes are still the mainstay of materials, although we are seeing many custom medical-grade material blends, colors, and custom diameters, including near-net shapes.

Dean Entrekin: Surface technology is a major area of research and implant innovation we are seeing today. Enhancements in additive manufacturing have allowed for unique porous titanium surfaces that stimulate bone ongrowth/ingrowth. Some research and development efforts have applied this surface porosity to other materials like PEEK, which has also shown bone apposition, unlike what you see with standard machined PEEK implants. The ultimate goal is a radiolucent implant that has strength properties that mimic bone and does not stress shield, while also providing a surface that is conducive to bone growth.

Adam Griebel: Stainless, cobalt chrome, titanium, and other legacy materials remain the go-to choices, due to their long history of implantation. Advances in processing technologies are enabling better performance out of proven materials. Absorbable metals, primarily magnesium alloys, continue to advance in properties and commercial readiness. Some orthopedic magnesium-based devices are already available in markets outside the U.S.

Michael Kell: Materials/material sciences are in overall good shape for the orthopedic device market. Polymer materials continue to evolve and find innovative spaces in the market. Implants are also doing well, as is general surgical instrumentation. Our plastic sales continue to improve year after year.

Daniel Stoettner: The market is very steady at this time. Some titanium-mill lead times are shorter than they were last year. Not many customers, if any, are requesting new materials. Testing and verification requirements on existing alloys are increasing at some OEMs, affecting contract manufacturers.

Crawford: What are the latest trends in materials? What are OEMs asking for?

Carbone: There is increased demand for specially modified polymers to be X-ray opaque. For example, barium sulfide is added to polymers such as PPSU for good visibility and radiography. Another hot product is implantable PEEK filament for 3D printing applications.

Kell: PEEK seems to have a solid placement in all aspects of medical devices, particularly implants. While ultra-high-molecular-weight polyethylene (UHMWPE) remains steadfast, innovations in PEEK will continue well into the next decade. It seems nearly every month a new and improved implant utilizing PEEK comes to the market, and this is especially true for spinal applications. UHMWPE continues to move in a positive direction with a focus on antioxidated products where vitamin E and similar additives are being brought to the forefront of innovations.

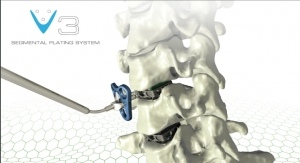

Steve Smith: Spinal components that were originally machined from PEEK or titanium bar are now being made with 3D printing using titanium powder, which creates a more porous structure and thereby enhances the rate of osseointegration following implantation. Development work is definitely being carried out on other applications, such as large joints, but these parts are generally manufactured from forgings or machined from wrought bar, processes which add greatly to the inherent properties of the finished components. However, as more advanced designs are developed using 3D printing technology, the mechanical properties will improve, and the parts will become more competitive with traditional casting, forging, and machining.

Stoettner: There is a slow move toward supplying existing alloys at a near-net shape to reduce lead times, reduce inventories, and increase cash flow. We are managing the entire condition of supply in many cases, including processing, testing, and verification—ultrasonic, mechanical, and chemical. We have added resources in order to address this need. By supplying near-net shapes, we help our OEM and contract manufacturing clients avoid deploying assets in operations with limited value-added input.

Crawford: What are some of the most creative things happening in the orthopedic space?

Griebel: Absorbable materials hold significant promise for the future of orthopedics, especially in trauma and sports medicine. Magnesium-based alloys have higher strength and stiffness than polymers, may promote new bone growth, and can degrade appropriately with proper alloy, process, and coating selection. Once implemented, these materials could improve patient outcomes and drive down cost by potentially eliminating the need for removal surgery.

Entrekin: At Viant, we’re developing a single-procedure intramedullary reamer shaft designed with unique carbon fiber. It has the flexibility needed for surgery, including design features to mitigate any risk of material fracture. New materials allow us to make economically responsible, yet high-performing single-procedure instruments, without the cleaning and sterilization issues of long-lumen reusable cannulated items. We’ve partnered with a unique supplier that could create shafts that meet our design specifications through a rolling process.

Griebel: Advanced metalworking processes like equal channel angular pressing (ECAP) shows promise to increase the strength of standard materials through microstructural refinement. ECAP is a unique process that creates an ultra-fine grain microstructure, which enhances the mechanical properties of different alloys that are put through the process. While not yet introduced into the orthopedic space, we believe that biocompatible ultra-fine grain materials such as titanium will create opportunities for innovation due to the fact that they are higher strength than conventional alloys, allowing smaller devices to be made, which may promote faster healing. While there is more research to be done, the initial foray into these unique materials has been very promising.

Carbone: Modern Plastics has a stocking program for colored medical grade PROPYLUX HS rod and colored medical grade PPSU RADEL rod for instrumentation and orthopedic trials. The stocking program allows orthopedic manufacturers and their contract manufacturers direct access to medical-grade rod in a wide variety of colors and diameters. Custom colors and custom rod diameters are also available.

Crawford: Most OEMs prefer to use traditional materials when they can because they are well studied and lower risk—yet newer materials with higher-performing engineered properties have great appeal. What determines the crossover between using traditional materials or newer materials?

Griebel: The value proposition must be very high for an OEM to introduce a new material. Moderate increases in performance typically will not be sufficient. Drivers of that value proposition could include elimination of certain elements, such as nickel or cobalt, or paradigm shifts—for example, using absorbable metals. An often-overlooked area of materials development is processing. Changes in the manufacturing route for any given alloy can result in significant changes in functional properties. For example, refining the microstructure of commercially pure titanium through processes like ECAP can drive strength and fatigue properties beyond those attainable in traditional titanium alloys like Ti-6Al-4V ELI.

Entrekin: The major roadblock for developing new implantable materials is the regulatory pathway. OEM leaders must weigh the risks and rewards of the investment required to prove safety and efficacy. In most cases, the mindset is “develop a better mouse trap” rather than “find a new way to catch the mouse.” When a technological leap is the goal, large OEMs will often acquire a company that already has that technology rather than developing it from scratch in-house.

Smith: Traditional materials used in orthopedics have plenty of empirical data based on many decades of actual in-patient use. This creates a barrier to entry for new materials. Generally speaking, development work on new materials is done by smaller companies looking for an edge into the market, or perhaps a surgeon determined to find a material solution to an issue that arose during surgery. As an example, the FDA recently approved a pedicle screw manufactured out of molybdenum-rhenium superalloy, which is believed to be the first alloy approved for implant that is not based on titanium, cobalt, or iron.

Entrekin: This material, MoRe, is the first new material approved by the FDA for orthopedics in decades. MoRe is a proprietary superalloy [developed by Mirus LLC] for medical device implants that purportedly combines strength, ductility and durability. This could result in smaller, stronger implants requiring less disruption of native tissue.

Kell: Ultimately, it is all about patient outcome, and a little about the bottom line as well. If the newer material fits patient demand, and it makes sense from a financial viewpoint, then orthopedic OEMs and material developers will find a way to make it happen.

Crawford: Do OEMs and their contract manufacturers work with material companies to co-develop proprietary materials just for themselves?

Carbone: Yes, in some cases OEMs and contract manufacturers work to develop a proprietary material for a specific application. The testing, feasibility, and developing a specification around the new material can be time-consuming and incredibly expensive. However, developing a proprietary material for a specific application provides the OEM and contract manufacturer with an advantage over competitors. Also, a part or product that mechanically outperforms what’s currently on the market will provide significant advantages.

Kell: I would say only the biggest contract manufacturers get involved at this level of development, and they typically have the resources to do so. They rely on the OEM to deal with regulatory, but often help in that process. Most of the new developments happening for polymer materials would start with the OEM and its internal research and development team. From there, outside help is brought to the table, especially for bigger projects.

Entrekin: The academic setting is where the most exciting material science advancements in implantable materials usually happen. OEMs often find a university-based group working on a specific material and work to license this technology. The regulatory pathway is the largest deterrent to material advancements in the orthopedic space. Most executive leaders do not have the time or runway to see a new material developed, clinically tested, approved, and commercialized. This has led to larger OEMs acquiring small development engine-type companies that spin off from university research groups and have already done much of the development leg work already.

Smith: Some OEMs work with the manufacturing mills to develop variations to existing medical-grade materials primarily in order to respond to concerns with existing materials raised by surgeons and patients. For example, a small percentage of the population is susceptible to nickel allergies, so a segment of the market is looking to develop nickel-free devices. However, what exactly constitutes “nickel-free” in a metal component when trace amounts of many elements are inherent in the alloy? Then, once you have defined your “new” material, you have to prove the benefits and convince the FDA and other regulatory bodies, which is a lengthy and costly process. However, there are many niche market segments, which can prove to be very profitable, so the effort can be worth it in the long run.

Crawford: What are the latest developments with AM/3DP materials?

Entrekin: The common theme for the past several years is printing porous titanium constructs for large-joint, spine, and extremity indications. This has allowed small incubator-type companies to get off the ground quickly with minimal investment. This has also flooded the industry with “me-too” implants, each with their own take on structure and surface porosity.

Smith: Additive manufacturing of orthopedic components is a growing segment of the market. Standard and complex spine cages are now reaching the mass market, due to the advantages of higher bone in-growth, the removal of the coating phase, and a generally easier manufacturing process. Customized implants, albeit a niche market, allow greater flexibility in design and removes many steps in the manufacturing process. According to a recent presentation by Avicenne Medical, 3D-printed parts accounted for just over 5 percent of the hip, knee, shoulder, and trauma segments, and is projected to rise to almost 8 percent by 2021.

Entrekin: There is also a handful of companies working on additive-manufactured PEEK, which is very interesting because this material is difficult to apply to a 3D printer. There are university groups investigating additive manufacturing in orthobiologics, printing everything from bone scaffolds to collagen scaffolds, which could in time mitigate the need for allograft in soft tissue and boney indications. Additive manufacturing will never replace traditional manufacturing, but it’s another tool in the tool belt of design engineers and material scientists to continue to push the envelope in implant innovation.

Carbone: Absolutely and without a doubt, it is PEEK filament. Evonik has become the first company in the world to develop a polymer filament based on PEEK in implant-grade quality for use as a 3D printing material for implants. This high-performance material can be used in fused filament fabrication (FFF) technology and is expected to enable additive production of three-dimensional plastic parts for medical implants in the human body. The filament exhibits impressive biocompatibility, biostability, and X-ray transparency, is easy to process, and has been established for years as a high-performance material in medical technology applications such as spinal implants, sports medicine, and maxillofacial surgery.

Crawford: In closing, what do OEMs tend to misunderstand about materials? Are there any common questions or issues we can clarify?

Entrekin: Material selection can be critical in the overall effectiveness of a product. Novel materials can often be used to improve product performance in ways that weren’t possible with traditional materials. For example, an orthopedic customer wanted help with a redesign of an instrument set. One of the issues we encountered was the product markings became hard to read after a stainless-steel instrument was repeatedly cleaned and sterilized. We developed a patented 2-shot molding process using a modified PEEK material with contrasting colors that made product markings easier to read and impervious to the cleaning and sterilizing procedures that the previous material couldn’t withstand—effectively addressing a surgeon complaint.

Smith: There can be a tendency to be more concerned about dotting the i’s and crossing the t’s on the paperwork, than about the actual chemical and mechanical properties of the material. In-house specifications that tweak a standard specification generally add to the cost and limit availability. As a distributor, you can have material in stock that meets all the chemistry and mechanical properties for a project, but the mill certification does not include a specific OEM in-house specification. This leads to re-testing and re-certification, all of which takes unnecessary time and money.

Stoettner: As increased testing requirements are implemented, their impact on existing supply chains is not well understood. As an example, increased requests to ultrasonically test bar to a higher standard can create challenges in existing supply. Potential yield loss on single melt alloys can be significant, which increases lead times and increases raw material costs. Banner has expertise to help manage and mitigate customer risk. In many cases, mill lead times are underestimated, as well as minimum order quantities. We continue to work with our customers to reduce both.

Kell: One misunderstanding deals with availability. Many chemical companies want to bring products into this market space, but it’s mostly their raw material for injection molding. Orthopedics use a good amount of extruded and molded materials, so these resin manufacturers need to be more aware of the final product that is required.

Smith: OEMs also need to remember that, although the orthopedic market is a (U.S.) $50-billion market, the raw materials used in the industry are a relatively small, albeit very important, portion of that total. Furthermore, the orthopedic use of those raw materials is a small percentage of total overall use. For example, titanium is a major material for orthopedic implants, but the medical market only accounts for 3 percent of the overall consumption of titanium. Therefore, fluctuating demand from other industries, particularly aerospace with 42 percent of overall titanium consumption, has a much greater impact on pricing and mill lead times. Hence it benefits both the OEM and the contract manufacturer to work with stocking distributors specializing in medical grade raw materials to ensure a constant source of supply.

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.

Material science is rapidly evolving to meet the needs of disruptive new manufacturing technologies such as additive manufacturing (AM) and 3D printing (3DP). Advanced injection molding can now process a wider range of polymers and even metals for key product applications. New or enhanced materials give engineers more options for creative orthopedic device designs, higher functionality, and improved patient outcomes.

Material science innovations include advanced resorbable materials, antimicrobial coatings, biodegradable metals, and bioprinting of live cells. New metalworking processes can increase the strength of standard materials by refining microstructural design. AM/3DP processes and materials allow engineers and designers to think “outside the box” and create highly functional products that cannot be made any other way.

Despite these exciting advances, orthopedic OEMs tend to remain very conservative when it comes to choosing materials for their implants and instrumentation. Adoption of new materials tends to only happen when a new design requires some level of functionality that well-tested, FDA-approved legacy materials simply cannot offer.

That said, OEMs must embrace new materials to stay on the cutting edge of technology, remain competitive, and gain market share. As demand increases for smaller, more complex, and more functional devices with highly-specific engineered material properties, medical device manufacturers (MDMs) must keep up with the latest advances in material science, such as new metal alloys, polymer/metal hybrids, bioabsorbable polymers, biocomposite polymers/ceramics, and bioprinting. Even with all these material options to consider, new materials with unique properties continue to be announced on a regular basis, especially for AM/3D printing.

To better understand the factors driving material trends in the orthopedic industry, Orthopedic Design and Technology (ODT) spoke with six industry experts who shared their insights regarding how materials are used in the design and manufacture of orthopedic products. These experts are:

-

Bing Carbone, president of Modern Plastics, a Shelton, Conn.-based supplier of high-performance medical-grade plastics.

-

Dean Entrekin, director of technical solutions for orthopedics for Viant Medical, a Foxborough, Mass.-based provider of medical device solutions.

-

Adam Griebel, senior research and development engineer for Fort Wayne Metals Research Products Corporation, a Fort Wayne, Ind.-based manufacturer of precision wires, strands, and cables for medical devices.

-

Michael Kell, business development manager for life sciences at the Harrisburg, Pa., branch of Total Plastics, a distributor of plastic sheet, rod, tube, and film.

-

Steve Smith, president of Edge International in Dayton, Ohio, a division of Titan Metal Fabricators, that provides titanium sheet, plate, and bar.

- Daniel Stoettner, executive vice president and COO for Banner Medical Innovations, a Carol Stream, Ill.-based contract manufacturer for the medical device industry.

Mark Crawford: What is the overall state of materials/materials science in the orthopedic device market today?

Bing Carbone: We continue to see usage of traditional medical plastics materials, but advanced materials are now ready for the market, or will be forthcoming. Materials like polyetheretherketone (PEEK), polyphenylsulfone, (PPSU), poly(methyl methacrylate) (PMMA), medical-grade acetal co-polymers, and heat-stabilized polypropylenes are still the mainstay of materials, although we are seeing many custom medical-grade material blends, colors, and custom diameters, including near-net shapes.

Dean Entrekin: Surface technology is a major area of research and implant innovation we are seeing today. Enhancements in additive manufacturing have allowed for unique porous titanium surfaces that stimulate bone ongrowth/ingrowth. Some research and development efforts have applied this surface porosity to other materials like PEEK, which has also shown bone apposition, unlike what you see with standard machined PEEK implants. The ultimate goal is a radiolucent implant that has strength properties that mimic bone and does not stress shield, while also providing a surface that is conducive to bone growth.

Adam Griebel: Stainless, cobalt chrome, titanium, and other legacy materials remain the go-to choices, due to their long history of implantation. Advances in processing technologies are enabling better performance out of proven materials. Absorbable metals, primarily magnesium alloys, continue to advance in properties and commercial readiness. Some orthopedic magnesium-based devices are already available in markets outside the U.S.

Michael Kell: Materials/material sciences are in overall good shape for the orthopedic device market. Polymer materials continue to evolve and find innovative spaces in the market. Implants are also doing well, as is general surgical instrumentation. Our plastic sales continue to improve year after year.

Daniel Stoettner: The market is very steady at this time. Some titanium-mill lead times are shorter than they were last year. Not many customers, if any, are requesting new materials. Testing and verification requirements on existing alloys are increasing at some OEMs, affecting contract manufacturers.

Crawford: What are the latest trends in materials? What are OEMs asking for?

Carbone: There is increased demand for specially modified polymers to be X-ray opaque. For example, barium sulfide is added to polymers such as PPSU for good visibility and radiography. Another hot product is implantable PEEK filament for 3D printing applications.

Kell: PEEK seems to have a solid placement in all aspects of medical devices, particularly implants. While ultra-high-molecular-weight polyethylene (UHMWPE) remains steadfast, innovations in PEEK will continue well into the next decade. It seems nearly every month a new and improved implant utilizing PEEK comes to the market, and this is especially true for spinal applications. UHMWPE continues to move in a positive direction with a focus on antioxidated products where vitamin E and similar additives are being brought to the forefront of innovations.

Steve Smith: Spinal components that were originally machined from PEEK or titanium bar are now being made with 3D printing using titanium powder, which creates a more porous structure and thereby enhances the rate of osseointegration following implantation. Development work is definitely being carried out on other applications, such as large joints, but these parts are generally manufactured from forgings or machined from wrought bar, processes which add greatly to the inherent properties of the finished components. However, as more advanced designs are developed using 3D printing technology, the mechanical properties will improve, and the parts will become more competitive with traditional casting, forging, and machining.

Stoettner: There is a slow move toward supplying existing alloys at a near-net shape to reduce lead times, reduce inventories, and increase cash flow. We are managing the entire condition of supply in many cases, including processing, testing, and verification—ultrasonic, mechanical, and chemical. We have added resources in order to address this need. By supplying near-net shapes, we help our OEM and contract manufacturing clients avoid deploying assets in operations with limited value-added input.

Crawford: What are some of the most creative things happening in the orthopedic space?

Griebel: Absorbable materials hold significant promise for the future of orthopedics, especially in trauma and sports medicine. Magnesium-based alloys have higher strength and stiffness than polymers, may promote new bone growth, and can degrade appropriately with proper alloy, process, and coating selection. Once implemented, these materials could improve patient outcomes and drive down cost by potentially eliminating the need for removal surgery.

Entrekin: At Viant, we’re developing a single-procedure intramedullary reamer shaft designed with unique carbon fiber. It has the flexibility needed for surgery, including design features to mitigate any risk of material fracture. New materials allow us to make economically responsible, yet high-performing single-procedure instruments, without the cleaning and sterilization issues of long-lumen reusable cannulated items. We’ve partnered with a unique supplier that could create shafts that meet our design specifications through a rolling process.

Griebel: Advanced metalworking processes like equal channel angular pressing (ECAP) shows promise to increase the strength of standard materials through microstructural refinement. ECAP is a unique process that creates an ultra-fine grain microstructure, which enhances the mechanical properties of different alloys that are put through the process. While not yet introduced into the orthopedic space, we believe that biocompatible ultra-fine grain materials such as titanium will create opportunities for innovation due to the fact that they are higher strength than conventional alloys, allowing smaller devices to be made, which may promote faster healing. While there is more research to be done, the initial foray into these unique materials has been very promising.

Carbone: Modern Plastics has a stocking program for colored medical grade PROPYLUX HS rod and colored medical grade PPSU RADEL rod for instrumentation and orthopedic trials. The stocking program allows orthopedic manufacturers and their contract manufacturers direct access to medical-grade rod in a wide variety of colors and diameters. Custom colors and custom rod diameters are also available.

Crawford: Most OEMs prefer to use traditional materials when they can because they are well studied and lower risk—yet newer materials with higher-performing engineered properties have great appeal. What determines the crossover between using traditional materials or newer materials?

Griebel: The value proposition must be very high for an OEM to introduce a new material. Moderate increases in performance typically will not be sufficient. Drivers of that value proposition could include elimination of certain elements, such as nickel or cobalt, or paradigm shifts—for example, using absorbable metals. An often-overlooked area of materials development is processing. Changes in the manufacturing route for any given alloy can result in significant changes in functional properties. For example, refining the microstructure of commercially pure titanium through processes like ECAP can drive strength and fatigue properties beyond those attainable in traditional titanium alloys like Ti-6Al-4V ELI.

Entrekin: The major roadblock for developing new implantable materials is the regulatory pathway. OEM leaders must weigh the risks and rewards of the investment required to prove safety and efficacy. In most cases, the mindset is “develop a better mouse trap” rather than “find a new way to catch the mouse.” When a technological leap is the goal, large OEMs will often acquire a company that already has that technology rather than developing it from scratch in-house.

Smith: Traditional materials used in orthopedics have plenty of empirical data based on many decades of actual in-patient use. This creates a barrier to entry for new materials. Generally speaking, development work on new materials is done by smaller companies looking for an edge into the market, or perhaps a surgeon determined to find a material solution to an issue that arose during surgery. As an example, the FDA recently approved a pedicle screw manufactured out of molybdenum-rhenium superalloy, which is believed to be the first alloy approved for implant that is not based on titanium, cobalt, or iron.

Entrekin: This material, MoRe, is the first new material approved by the FDA for orthopedics in decades. MoRe is a proprietary superalloy [developed by Mirus LLC] for medical device implants that purportedly combines strength, ductility and durability. This could result in smaller, stronger implants requiring less disruption of native tissue.

Kell: Ultimately, it is all about patient outcome, and a little about the bottom line as well. If the newer material fits patient demand, and it makes sense from a financial viewpoint, then orthopedic OEMs and material developers will find a way to make it happen.

Crawford: Do OEMs and their contract manufacturers work with material companies to co-develop proprietary materials just for themselves?

Carbone: Yes, in some cases OEMs and contract manufacturers work to develop a proprietary material for a specific application. The testing, feasibility, and developing a specification around the new material can be time-consuming and incredibly expensive. However, developing a proprietary material for a specific application provides the OEM and contract manufacturer with an advantage over competitors. Also, a part or product that mechanically outperforms what’s currently on the market will provide significant advantages.

Kell: I would say only the biggest contract manufacturers get involved at this level of development, and they typically have the resources to do so. They rely on the OEM to deal with regulatory, but often help in that process. Most of the new developments happening for polymer materials would start with the OEM and its internal research and development team. From there, outside help is brought to the table, especially for bigger projects.

Entrekin: The academic setting is where the most exciting material science advancements in implantable materials usually happen. OEMs often find a university-based group working on a specific material and work to license this technology. The regulatory pathway is the largest deterrent to material advancements in the orthopedic space. Most executive leaders do not have the time or runway to see a new material developed, clinically tested, approved, and commercialized. This has led to larger OEMs acquiring small development engine-type companies that spin off from university research groups and have already done much of the development leg work already.

Smith: Some OEMs work with the manufacturing mills to develop variations to existing medical-grade materials primarily in order to respond to concerns with existing materials raised by surgeons and patients. For example, a small percentage of the population is susceptible to nickel allergies, so a segment of the market is looking to develop nickel-free devices. However, what exactly constitutes “nickel-free” in a metal component when trace amounts of many elements are inherent in the alloy? Then, once you have defined your “new” material, you have to prove the benefits and convince the FDA and other regulatory bodies, which is a lengthy and costly process. However, there are many niche market segments, which can prove to be very profitable, so the effort can be worth it in the long run.

Crawford: What are the latest developments with AM/3DP materials?

Entrekin: The common theme for the past several years is printing porous titanium constructs for large-joint, spine, and extremity indications. This has allowed small incubator-type companies to get off the ground quickly with minimal investment. This has also flooded the industry with “me-too” implants, each with their own take on structure and surface porosity.

Smith: Additive manufacturing of orthopedic components is a growing segment of the market. Standard and complex spine cages are now reaching the mass market, due to the advantages of higher bone in-growth, the removal of the coating phase, and a generally easier manufacturing process. Customized implants, albeit a niche market, allow greater flexibility in design and removes many steps in the manufacturing process. According to a recent presentation by Avicenne Medical, 3D-printed parts accounted for just over 5 percent of the hip, knee, shoulder, and trauma segments, and is projected to rise to almost 8 percent by 2021.

Entrekin: There is also a handful of companies working on additive-manufactured PEEK, which is very interesting because this material is difficult to apply to a 3D printer. There are university groups investigating additive manufacturing in orthobiologics, printing everything from bone scaffolds to collagen scaffolds, which could in time mitigate the need for allograft in soft tissue and boney indications. Additive manufacturing will never replace traditional manufacturing, but it’s another tool in the tool belt of design engineers and material scientists to continue to push the envelope in implant innovation.

Carbone: Absolutely and without a doubt, it is PEEK filament. Evonik has become the first company in the world to develop a polymer filament based on PEEK in implant-grade quality for use as a 3D printing material for implants. This high-performance material can be used in fused filament fabrication (FFF) technology and is expected to enable additive production of three-dimensional plastic parts for medical implants in the human body. The filament exhibits impressive biocompatibility, biostability, and X-ray transparency, is easy to process, and has been established for years as a high-performance material in medical technology applications such as spinal implants, sports medicine, and maxillofacial surgery.

Crawford: In closing, what do OEMs tend to misunderstand about materials? Are there any common questions or issues we can clarify?

Entrekin: Material selection can be critical in the overall effectiveness of a product. Novel materials can often be used to improve product performance in ways that weren’t possible with traditional materials. For example, an orthopedic customer wanted help with a redesign of an instrument set. One of the issues we encountered was the product markings became hard to read after a stainless-steel instrument was repeatedly cleaned and sterilized. We developed a patented 2-shot molding process using a modified PEEK material with contrasting colors that made product markings easier to read and impervious to the cleaning and sterilizing procedures that the previous material couldn’t withstand—effectively addressing a surgeon complaint.

Smith: There can be a tendency to be more concerned about dotting the i’s and crossing the t’s on the paperwork, than about the actual chemical and mechanical properties of the material. In-house specifications that tweak a standard specification generally add to the cost and limit availability. As a distributor, you can have material in stock that meets all the chemistry and mechanical properties for a project, but the mill certification does not include a specific OEM in-house specification. This leads to re-testing and re-certification, all of which takes unnecessary time and money.

Stoettner: As increased testing requirements are implemented, their impact on existing supply chains is not well understood. As an example, increased requests to ultrasonically test bar to a higher standard can create challenges in existing supply. Potential yield loss on single melt alloys can be significant, which increases lead times and increases raw material costs. Banner has expertise to help manage and mitigate customer risk. In many cases, mill lead times are underestimated, as well as minimum order quantities. We continue to work with our customers to reduce both.

Kell: One misunderstanding deals with availability. Many chemical companies want to bring products into this market space, but it’s mostly their raw material for injection molding. Orthopedics use a good amount of extruded and molded materials, so these resin manufacturers need to be more aware of the final product that is required.

Smith: OEMs also need to remember that, although the orthopedic market is a (U.S.) $50-billion market, the raw materials used in the industry are a relatively small, albeit very important, portion of that total. Furthermore, the orthopedic use of those raw materials is a small percentage of total overall use. For example, titanium is a major material for orthopedic implants, but the medical market only accounts for 3 percent of the overall consumption of titanium. Therefore, fluctuating demand from other industries, particularly aerospace with 42 percent of overall titanium consumption, has a much greater impact on pricing and mill lead times. Hence it benefits both the OEM and the contract manufacturer to work with stocking distributors specializing in medical grade raw materials to ensure a constant source of supply.

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.