Jack Wieland, Project Manager, Lowell Inc.08.17.21

First article inspection (FAI) is a necessary step to ensure a manufacturing process will create a medical device that works as designed and meets requirements. It is a near-to-100-percent inspection of the first part that comes off a machine. The data and measurements gathered from FAI become part of the medical device file, which is required for FDA submissions and ISO 13485.

The FAI also builds confidence in the manufacturing process. Once it is submitted and approved, it’s assumed the same process will be in place for every part produced after that.

From a contract manufacturer’s perspective, a smooth FAI is important to its OEM customer’s satisfaction. It is a detailed process that improves with good communication and documentation practices.

Based on our experience, there are a number of ways to improve the FAI process. Following are four keys to success for your next project.

Key 1: A Well-Communicated Plan

While FAI is a standard expectation from OEMs, FAI requirements vary from company to company. Building out a well-documented and communicated plan is important to meeting everyone’s expectations.

Numerous customer questions around FAI are related to the method of inspection or how the inspection of certain features will be handled. For example, these questions frequently arise when a part has to be cut in half to inspect interior features that can’t be reached otherwise. “How many parts should be included in first article inspection?” “Should there be one part that’s used for all inspections, or should there be two or three—one intact, one cut in half for internal features, and one for surface finish?”

The answers to these questions will inform how a manufacturer approaches FAI, and are important for avoiding potential issues with inspection.

Key 2: Provide Parts to Clarify Subjective Features

Some features of medical devices are objective, such as measuring a radius or a length. There is a specific dimension and tolerance that needs to be met to pass FAI.

For more subjective features like color, shiny, and sharp, nothing works better than to have representative samples of what’s been produced previously. This gives the manufacturer a concrete example of the OEM’s expectations.

If you’re working with multiple manufacturers, these samples become even more relevant. When different parts from different manufacturers are in the same tray, they need to be consistent in fit, form, and function. From a surgeon’s perspective, the parts need to be indistinguishable from each other so there’s no confusion about the device being used.

All of these things can be more easily achieved through referencing representative samples before a project begins. These samples can also be used for comparison during FAI.

Key 3: Verify How Inspection Results Are Presented

Some OEMs provide inspection forms to their suppliers, and others look to the supplier to provide their own report. Reviewing how to report inspection results and which forms are required is a good step to take during pre-production meetings, so the inspection process can be customized to meet requirements. This conversation should review the order of paperwork to avoid issues later.

It’s also important to understand how data should be presented within the forms. Decimal points are a good example. Electronic inspection forms may be set up to display a certain number of digits after a decimal point. Ensuring the value recorded makes sense with respect to how the dimension is displayed on a drawing is critical for avoiding confusion down the road.

For example, if a drawing displays a dimension as .015 and the value recorded on the inspection report is .01, questions may arise about how this dimension was inspected and if a proper resolution gage was used. Developing a detailed inspection plan that includes proper gage resolution for each measured feature helps avoid this issue and can ensure results are presented as required.

Key 4: Design for Manufacturability

Because the manufacturing process is considered final once FAI is accepted, there is substantial work that goes into manufacturing a part that’s ready for first article inspection. A manufacturer has to program the machines and will likely machine several parts before fine-tuning the process and presenting an OEM with FAI parts and data. As part of that fine-tuning process, the manufacturer may discover opportunities to improve a part’s manufacturability or design. It will present these to the OEM for consideration.

One example is in tolerances. In some cases, there are opportunities to loosen a tolerance without sacrificing function or design intent, and improve consistency in manufacturing. When this happens, it can lead to time or cost savings if different equipment can be used or a higher throughput can be achieved.

One customer encountered an FAI issue with extremely tight tolerances on a bead. After finding it challenging to consistently manufacture the part, we explored ways to loosen the tolerance without impacting results. By finding the sweet spot in tolerance, the customer was able to update the print, we updated our manufacturing process, and the part passed FAI.

Manufacturers must also pay attention to tolerance stackups. When the inspection department takes a detailed look at a part’s dimensions or tolerance scheme, they may find ways to avoid issues with tolerance stackups. These findings are presented to the OEM, and if accepted, may improve FAI success.

One example is in a device with two components that go together. The manufacturer might find during testing that certain features on one component have to be held toward the lower tolerance limit and other features on the other component have to be held near the upper tolerance limit for the device to function the way the OEM expects. These results may lead to drawing updates by the OEM that may help the manufacturer pass a first article inspection.

Strong Collaboration/Communication for a More Successful FAI

A successful first article inspection is the first step of larger-scale production for medical devices. Without FAI approval, there isn’t proof a manufacturer’s production process and results meet expectations.

To make FAI more successful, OEMs and their contract manufacturers should document an inspection plan, review data and reporting requirements, and explore production options to make devices easier to manufacture consistently. This collaboration and communication is the best way to ensure shared success.

Jack Wieland is a project manager at Lowell and currently manages Lowell’s New Product Introduction team. He holds a bachelor’s degree in chemical engineering from the University of Minnesota Duluth and a master’s degree in manufacturing engineering from the University of St. Thomas. Since he started at Lowell in 2017, he has worked on several key projects, including the development and validation of a statistical analysis macro for Minitab as well as migrating Lowell’s entire quality management system to a software solution. Jack is a certified ISO13485:2016 lead auditor and is currently pursuing a Project Management Professional certification from the Project Management Institute.

The FAI also builds confidence in the manufacturing process. Once it is submitted and approved, it’s assumed the same process will be in place for every part produced after that.

From a contract manufacturer’s perspective, a smooth FAI is important to its OEM customer’s satisfaction. It is a detailed process that improves with good communication and documentation practices.

Based on our experience, there are a number of ways to improve the FAI process. Following are four keys to success for your next project.

Key 1: A Well-Communicated Plan

While FAI is a standard expectation from OEMs, FAI requirements vary from company to company. Building out a well-documented and communicated plan is important to meeting everyone’s expectations.

Numerous customer questions around FAI are related to the method of inspection or how the inspection of certain features will be handled. For example, these questions frequently arise when a part has to be cut in half to inspect interior features that can’t be reached otherwise. “How many parts should be included in first article inspection?” “Should there be one part that’s used for all inspections, or should there be two or three—one intact, one cut in half for internal features, and one for surface finish?”

The answers to these questions will inform how a manufacturer approaches FAI, and are important for avoiding potential issues with inspection.

Key 2: Provide Parts to Clarify Subjective Features

Some features of medical devices are objective, such as measuring a radius or a length. There is a specific dimension and tolerance that needs to be met to pass FAI.

For more subjective features like color, shiny, and sharp, nothing works better than to have representative samples of what’s been produced previously. This gives the manufacturer a concrete example of the OEM’s expectations.

If you’re working with multiple manufacturers, these samples become even more relevant. When different parts from different manufacturers are in the same tray, they need to be consistent in fit, form, and function. From a surgeon’s perspective, the parts need to be indistinguishable from each other so there’s no confusion about the device being used.

All of these things can be more easily achieved through referencing representative samples before a project begins. These samples can also be used for comparison during FAI.

Key 3: Verify How Inspection Results Are Presented

Some OEMs provide inspection forms to their suppliers, and others look to the supplier to provide their own report. Reviewing how to report inspection results and which forms are required is a good step to take during pre-production meetings, so the inspection process can be customized to meet requirements. This conversation should review the order of paperwork to avoid issues later.

It’s also important to understand how data should be presented within the forms. Decimal points are a good example. Electronic inspection forms may be set up to display a certain number of digits after a decimal point. Ensuring the value recorded makes sense with respect to how the dimension is displayed on a drawing is critical for avoiding confusion down the road.

For example, if a drawing displays a dimension as .015 and the value recorded on the inspection report is .01, questions may arise about how this dimension was inspected and if a proper resolution gage was used. Developing a detailed inspection plan that includes proper gage resolution for each measured feature helps avoid this issue and can ensure results are presented as required.

Key 4: Design for Manufacturability

Because the manufacturing process is considered final once FAI is accepted, there is substantial work that goes into manufacturing a part that’s ready for first article inspection. A manufacturer has to program the machines and will likely machine several parts before fine-tuning the process and presenting an OEM with FAI parts and data. As part of that fine-tuning process, the manufacturer may discover opportunities to improve a part’s manufacturability or design. It will present these to the OEM for consideration.

One example is in tolerances. In some cases, there are opportunities to loosen a tolerance without sacrificing function or design intent, and improve consistency in manufacturing. When this happens, it can lead to time or cost savings if different equipment can be used or a higher throughput can be achieved.

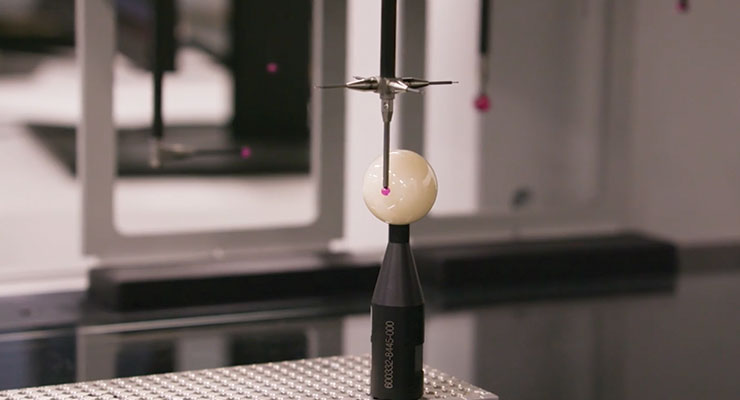

One customer encountered an FAI issue with extremely tight tolerances on a bead. After finding it challenging to consistently manufacture the part, we explored ways to loosen the tolerance without impacting results. By finding the sweet spot in tolerance, the customer was able to update the print, we updated our manufacturing process, and the part passed FAI.

Manufacturers must also pay attention to tolerance stackups. When the inspection department takes a detailed look at a part’s dimensions or tolerance scheme, they may find ways to avoid issues with tolerance stackups. These findings are presented to the OEM, and if accepted, may improve FAI success.

One example is in a device with two components that go together. The manufacturer might find during testing that certain features on one component have to be held toward the lower tolerance limit and other features on the other component have to be held near the upper tolerance limit for the device to function the way the OEM expects. These results may lead to drawing updates by the OEM that may help the manufacturer pass a first article inspection.

Strong Collaboration/Communication for a More Successful FAI

A successful first article inspection is the first step of larger-scale production for medical devices. Without FAI approval, there isn’t proof a manufacturer’s production process and results meet expectations.

To make FAI more successful, OEMs and their contract manufacturers should document an inspection plan, review data and reporting requirements, and explore production options to make devices easier to manufacture consistently. This collaboration and communication is the best way to ensure shared success.

Jack Wieland is a project manager at Lowell and currently manages Lowell’s New Product Introduction team. He holds a bachelor’s degree in chemical engineering from the University of Minnesota Duluth and a master’s degree in manufacturing engineering from the University of St. Thomas. Since he started at Lowell in 2017, he has worked on several key projects, including the development and validation of a statistical analysis macro for Minitab as well as migrating Lowell’s entire quality management system to a software solution. Jack is a certified ISO13485:2016 lead auditor and is currently pursuing a Project Management Professional certification from the Project Management Institute.