Dr. Mehdi Kazemzadeh-Narbat, Dr. Sherry Parker and Dr. Kim Ehman, WuXi AppTec05.26.22

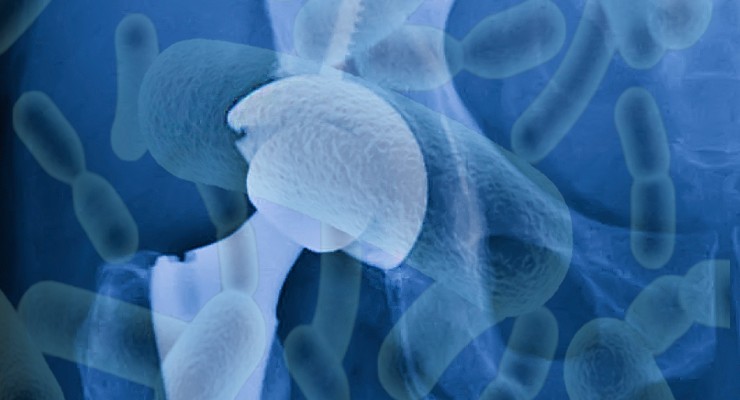

Orthopedic implant-associated infections, biofilm formation, and development of antibiotic resistant organisms can all lead to implant failure. Prosthetic joint infection (PJI) related to orthopedic implants is a potentially devastating medical complication that leaves patients with few options. In addition to aseptic loosening and pain, joint infections are a primary justification for implant revision surgeries. In fact, almost 15 percent of total hip arthroplasty and 25 percent of total knee arthroplasty revisions are due to infection.

Bacteria and fungi can colonize on the implant’s surface and cause an infection in the joint. PJI may occur within three months (early), three to 24 months (delayed), or after 24 months (late) after implantation. However, a far more severe condition occurs when biofilm develops. Biofilm is a structure consisting of multiple bacterial colonies that adhere to the implant’s surface and hide beneath a slimy extracellular matrix. Biofilm’s complex cellular composition makes it highly resistant to antibiotics. The only current treatment for acute PJI is an intrusive and dangerous debridement and implant retention (DAIR) procedure that could lead to amputation. Moreover, the implant revision is not always successful. The rate of recurrent or persistent infection following a two-stage revision surgery has been as high as 33 percent.

The financial challenges surrounding joint infection compound the physiological ones. The estimated cost of PJI treatment in the U.S. is $60,000-$100,000 per patient, not including surgery, post-acute care, or patient productivity loss. Moreover, U.S. reimbursement models do not cover complications like infection, placing the entire financial burden on patients, hospitals, and healthcare centers.

It is in everyone’s best interest to develop antimicrobial or ideally antibiofilm orthopedic implants. More of these devices would increase patient safety, save billions in annual healthcare costs, and reduce PJI occurrence. But the regulatory landscape surrounding antimicrobial-associated implants is challenging to navigate. There are very few clinically available devices of this nature, despite clear benefits to patients and providers.

Antimicrobial claims must prove the technology goes beyond bacteria and can eradicate microbes, spores, fungi, or other claimed pathogens. Antifouling claims should demonstrate the device’s coating or surface treatment repels or prevents bacteria and other microorganisms’ adherence to the surface. Antibiofilm is the boldest of the aforementioned claims. Antibiofilm claim data must show the technology can disrupt the biofilm matrix to expose and eradicate the bacteria, not just kill the planktonic (floating) bacteria. No approved products have thus far achieved the antibiofilm claim but some implants claim to prevent infection and disrupt biofilm via magnetic fields or electrical pulses.

The biggest challenge in approving medical devices with antimicrobial properties is the confusion between manufacturer claims and establishing regulatory special controls. The FDA has not yet recognized sufficient standards or published guidance on what must be included in these submissions. The agency has not seen enough submissions to develop benchmarks for which in-vitro and in-vivo testing or clinical data will establish safety and effectiveness. Thus, medical device manufacturers are unclear about the claims they can make, the preclinical studies linked to each claim, and acceptance criteria for each test conducted to support safety and achieve regulatory approval.

For preclinical testing, the FDA has yet to define the word “antibacterial” and consistently communicate its required colony-forming units reduction. Based on recent FDA feedback, anything less than a three-log reduction cannot be considered “antibacterial,” but examples exist of regulators requesting four- or even six-log reductions in-vitro. Any claims manufacturers make in their labeling should be demonstrated through performance testing, and the FDA will expect to see supporting data. However, peer-reviewed literature has not proven very helpful to waive preclinical testing.

As industry and regulatory collaborations continue to fill this gap by refining the guidance, some antimicrobial efficacy studies manufacturers can use include:

The biggest challenge in developing antimicrobial associated implants is to maintain their antimicrobial properties without impairing biocompatibility. An antimicrobial implant is unsafe if it is toxic or interferes with osteointegration or bone growth. Therefore, manufacturers should be prepared to meet FDA requirements according to ISO 10993-1 standards. The safety evaluation becomes more complicated if the antimicrobial associated implant is a combination product with an antimicrobial agent. In that case, the safety of the individual device and drug/biologics should be evaluated separately and together.

If the sponsor can provide sufficient evidence that the antimicrobial activity is physical-based and does not involve chemical action/being metabolized, the product would be considered a device and solely reviewed by CDRH. An example of non-chemical action is antimicrobial properties due to surface topography or electrostatic interaction. If the product contains a device, the antimicrobial activity involves chemical action/being metabolized for the achievement of its intended purposes, and the PMOA is attributed to the device, the product would be considered a combination product and multiple centers would review it, led by the CDRH. An example of chemical/metabolization action would be the use of conventional antibiotics such as penicillin or silver as an antimicrobial agent. However, if the PMOA is attributable to the antimicrobial component of the combination product, it would be assigned to the Center for Drug Evaluation and Research or Center for Biologics Evaluation and Research as the lead center with consultation from CDRH.

The bottom line with antimicrobial orthopedic devices is an unmet need—the FDA and medical device manufacturers both recognize it. This was highlighted when FDA held full day workshops on orthopedic device-related infections late last year, emphasizing the critical unmet need for alternatives to the current standard of care. However it currently is a vicious circle: The lack of regulatory standards or guidance means the industry does not know what level of information to provide to answer safety and effectiveness concerns. Perhaps if more manufacturers submitted these devices for review, regulators would better understand them and provide clearer guidance.

Next, manufacturers targeting orthopedic devices with antimicrobial claims must budget plenty of time to allow for uncertainties in the regulatory process. Manufacturers may consider a tiered approach, including multiple pre-submission meetings with the FDA to identify the regulatory pathway and receive guidance on the in-vitro, in-vivo, and clinical testing strategies.

Medical device manufacturers and stakeholders must prepare for a years-long process that includes multiple rounds of testing, gathering feedback, educating regulators, and trailblazing a new path for their device. But the payoff of bringing to market antimicrobial orthopedic medical devices that can save billions in healthcare costs and significantly reduce infection and patient suffering is worth the wait.

Dr. Mehdi Kazemzadeh-Narbat is a former FDA medical device lead reviewer and acting team lead with five years of FDA experience in medical device regulation. At MCRA, he provides guidance on regulatory strategies and submissions development across various therapies.

Dr. Sherry Parker has over 20 years of toxicology and medical device experience, and is an expert in biological evaluation of medical devices and combination products. In her current position as WuXi AppTec’s senior director of Regulatory Toxicology, Dr. Parker provides manufacturers with guidance on global regulatory and technical requirements and testing program design.

Dr. Kim Ehman, Ph.D., DABT, is a technical director of Regulatory Toxicology, with a focus on medical device and combination products. Dr. Ehman has over 18 years of toxicology and medical device experience. Prior to joining WuXi AppTec Medical Device Testing, she worked as a toxicologist for RTI International, Toxicology Regulatory Services, and Altria Client Services.

Bacteria and fungi can colonize on the implant’s surface and cause an infection in the joint. PJI may occur within three months (early), three to 24 months (delayed), or after 24 months (late) after implantation. However, a far more severe condition occurs when biofilm develops. Biofilm is a structure consisting of multiple bacterial colonies that adhere to the implant’s surface and hide beneath a slimy extracellular matrix. Biofilm’s complex cellular composition makes it highly resistant to antibiotics. The only current treatment for acute PJI is an intrusive and dangerous debridement and implant retention (DAIR) procedure that could lead to amputation. Moreover, the implant revision is not always successful. The rate of recurrent or persistent infection following a two-stage revision surgery has been as high as 33 percent.

The financial challenges surrounding joint infection compound the physiological ones. The estimated cost of PJI treatment in the U.S. is $60,000-$100,000 per patient, not including surgery, post-acute care, or patient productivity loss. Moreover, U.S. reimbursement models do not cover complications like infection, placing the entire financial burden on patients, hospitals, and healthcare centers.

It is in everyone’s best interest to develop antimicrobial or ideally antibiofilm orthopedic implants. More of these devices would increase patient safety, save billions in annual healthcare costs, and reduce PJI occurrence. But the regulatory landscape surrounding antimicrobial-associated implants is challenging to navigate. There are very few clinically available devices of this nature, despite clear benefits to patients and providers.

Choosing the Right Antimicrobial Claim

Classifying a device as antibacterial, antimicrobial, antifouling, or antibiofilm is complex. Whether it is gentamicin, penicillin, vancomycin, or silver, every antimicrobial agent is potent against specific bacterial spectrums. Per definition, the antibacterial claim is solely about bacteria, and usually the performance data must demonstrate the technology can kill or inhibit colonization of at least three-gram positive and three-gram negative prevalent planktonic bacteria for specific indications.Antimicrobial claims must prove the technology goes beyond bacteria and can eradicate microbes, spores, fungi, or other claimed pathogens. Antifouling claims should demonstrate the device’s coating or surface treatment repels or prevents bacteria and other microorganisms’ adherence to the surface. Antibiofilm is the boldest of the aforementioned claims. Antibiofilm claim data must show the technology can disrupt the biofilm matrix to expose and eradicate the bacteria, not just kill the planktonic (floating) bacteria. No approved products have thus far achieved the antibiofilm claim but some implants claim to prevent infection and disrupt biofilm via magnetic fields or electrical pulses.

Scope of the Problem

While some orthopedic products such as bone cements impregnated with antibiotics and antibiotic-eluting joint spacers have a long history of a 510(k) pathway with the FDA, almost all other devices combined with antimicrobial agents may not be considered eligible for that pathway. The FDA cleared a silver-coated bone screw in 1996, but regulatory changes have rendered the product an unacceptable 510(k) predicate for reducing bacterial colonization.The biggest challenge in approving medical devices with antimicrobial properties is the confusion between manufacturer claims and establishing regulatory special controls. The FDA has not yet recognized sufficient standards or published guidance on what must be included in these submissions. The agency has not seen enough submissions to develop benchmarks for which in-vitro and in-vivo testing or clinical data will establish safety and effectiveness. Thus, medical device manufacturers are unclear about the claims they can make, the preclinical studies linked to each claim, and acceptance criteria for each test conducted to support safety and achieve regulatory approval.

For preclinical testing, the FDA has yet to define the word “antibacterial” and consistently communicate its required colony-forming units reduction. Based on recent FDA feedback, anything less than a three-log reduction cannot be considered “antibacterial,” but examples exist of regulators requesting four- or even six-log reductions in-vitro. Any claims manufacturers make in their labeling should be demonstrated through performance testing, and the FDA will expect to see supporting data. However, peer-reviewed literature has not proven very helpful to waive preclinical testing.

As industry and regulatory collaborations continue to fill this gap by refining the guidance, some antimicrobial efficacy studies manufacturers can use include:

- Time-Kill test

- Agar Disk-Diffusion assay

- Antimicrobial release profile over time

- Resistance testing (e.g., Mu50 Susceptibility)

- Minimum Inhibitory Concentration and Minimum Effective Concentration values (in accordance with FDA recognized test methods developed by the Clinical and Laboratory Standards Institute such as M02, M07, and M100)

The biggest challenge in developing antimicrobial associated implants is to maintain their antimicrobial properties without impairing biocompatibility. An antimicrobial implant is unsafe if it is toxic or interferes with osteointegration or bone growth. Therefore, manufacturers should be prepared to meet FDA requirements according to ISO 10993-1 standards. The safety evaluation becomes more complicated if the antimicrobial associated implant is a combination product with an antimicrobial agent. In that case, the safety of the individual device and drug/biologics should be evaluated separately and together.

Choosing the Right Regulatory Pathway

The jurisdiction classification and assignment of antimicrobial products can be opaque because orthopedic devices integrated with antimicrobial features are a new category in the U.S. The Office of Combination Products (OCP) usually identifies a device’s primary mode of action (PMOA), which generally determines its regulatory pathway, but that determination is based on multiple factors.If the sponsor can provide sufficient evidence that the antimicrobial activity is physical-based and does not involve chemical action/being metabolized, the product would be considered a device and solely reviewed by CDRH. An example of non-chemical action is antimicrobial properties due to surface topography or electrostatic interaction. If the product contains a device, the antimicrobial activity involves chemical action/being metabolized for the achievement of its intended purposes, and the PMOA is attributed to the device, the product would be considered a combination product and multiple centers would review it, led by the CDRH. An example of chemical/metabolization action would be the use of conventional antibiotics such as penicillin or silver as an antimicrobial agent. However, if the PMOA is attributable to the antimicrobial component of the combination product, it would be assigned to the Center for Drug Evaluation and Research or Center for Biologics Evaluation and Research as the lead center with consultation from CDRH.

The bottom line with antimicrobial orthopedic devices is an unmet need—the FDA and medical device manufacturers both recognize it. This was highlighted when FDA held full day workshops on orthopedic device-related infections late last year, emphasizing the critical unmet need for alternatives to the current standard of care. However it currently is a vicious circle: The lack of regulatory standards or guidance means the industry does not know what level of information to provide to answer safety and effectiveness concerns. Perhaps if more manufacturers submitted these devices for review, regulators would better understand them and provide clearer guidance.

Available Options

First, collaborating with an experienced laboratory testing partner will help alleviate confusion and undue stress. A GLP-compliant lab partner that performs in-vivo and in-vitro antimicrobial testing can establish special controls for the FDA. The right partner can also help manufacturers use pre-submission meetings to confirm the testing pathway and define the next steps. Finally, the myriad in-vivo and in-vitro tests required to support a device’s safety claims requires many scientists with varying skill sets. A laboratory testing partner that can comprehensively support evaluations to address regulatory requirements will alleviate major headaches.Next, manufacturers targeting orthopedic devices with antimicrobial claims must budget plenty of time to allow for uncertainties in the regulatory process. Manufacturers may consider a tiered approach, including multiple pre-submission meetings with the FDA to identify the regulatory pathway and receive guidance on the in-vitro, in-vivo, and clinical testing strategies.

Medical device manufacturers and stakeholders must prepare for a years-long process that includes multiple rounds of testing, gathering feedback, educating regulators, and trailblazing a new path for their device. But the payoff of bringing to market antimicrobial orthopedic medical devices that can save billions in healthcare costs and significantly reduce infection and patient suffering is worth the wait.

Dr. Mehdi Kazemzadeh-Narbat is a former FDA medical device lead reviewer and acting team lead with five years of FDA experience in medical device regulation. At MCRA, he provides guidance on regulatory strategies and submissions development across various therapies.

Dr. Sherry Parker has over 20 years of toxicology and medical device experience, and is an expert in biological evaluation of medical devices and combination products. In her current position as WuXi AppTec’s senior director of Regulatory Toxicology, Dr. Parker provides manufacturers with guidance on global regulatory and technical requirements and testing program design.

Dr. Kim Ehman, Ph.D., DABT, is a technical director of Regulatory Toxicology, with a focus on medical device and combination products. Dr. Ehman has over 18 years of toxicology and medical device experience. Prior to joining WuXi AppTec Medical Device Testing, she worked as a toxicologist for RTI International, Toxicology Regulatory Services, and Altria Client Services.