James Dwyer, VP of Technical Operations, Millstone Medical Outsourcing LLC03.21.18

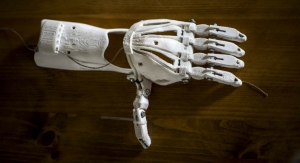

The leading cause of a surgical revision of an orthopedic implant is aseptic loosening1. Eight percent of arthroplasties performed in the United States undergo revisions due to aseptic loosening2; most often due to the presence of endotoxins3. Osteolysis (dissolution or degeneration of bone) is generally observed in the region of loosening. This pathological process is due to the particles that are generated by the implant. Endotoxins, if present, adhere to these particles and exacerbate the osteolysis and inhibit osseointegration (the firm anchoring of a surgical implant by the growth of bone around it without fibrous tissue formation at the interface) of the implant. If endotoxins enter the circulatory system, a febrile response along with tachypnea and hypotension may also result.

Endotoxins are mostly found in the cell wall (outer membrane) of Gram-negative bacteria. Endotoxins are lipopolysaccharides and the Lipid A portion of the heteropolysaccharide chain is responsible for the toxicity. The Lipid A is a powerful biological response modifier that can negatively stimulate the mammalian immune system. Endotoxins are constantly shed from viable gram-bacteria and when a gram-negative bacterium undergoes lysis, the entirety of its endotoxins is released from the cell into the immediate environment.

The FDA issued guidance on endotoxins in June of 2012. In this guidance, the CDRH adopted the USP Endotoxin Reference Standard and limits for medical device extracts. This standard expresses limits in units of EU, which is a measure of biological activity. Endotoxins vary in their potency to mass ratio; however, one EU equates to, approximately, 0.1-0.2 nanograms of endotoxin per ml of water. There are many caveats around this mass claim, however, it provides a rough correlation.

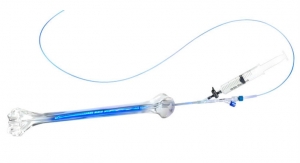

This guidance provides recommendations based upon the FDA’s current thinking. Specifically, it recommends an extraction volume limit of 0.5 EU/mL or 20 EU/device for devices that contact the cardiovascular system and lymphatic system directly or indirectly. For devices in contact with cerebrospinal fluid, the limit is 0.06 EU/mL or 2.15 EU/device. The limits for interocular devices is lower still at 0.215 EU/device. Most orthopedic devices fall into the less stringent limit of 20 EU/device. USP Chapter <161> Transfusion and Infusion Assemblies and Similar Medical Devices provide these limits.

Quality by design concepts are specifically addressed in the FDA guidance. The medical device manufacturer’s strategy for endotoxins should be based upon product and process knowledge. A comprehensive understanding of the potential sources of endotoxin contamination and monitoring of these sources are essential to ensure consistent final-product quality.

The United States Pharmacopeia (USP) <1231> can be a guide for a company’s USP water system whether it is utilizing a purified water system based upon reverse osmosis technology or distillation. However, there is no specification for bacterial endotoxins for purified water. So, the default is to utilize the more stringent specifications of WFI (water for injection). The WFI specification for endotoxins is 0.25 EU/mL. Understanding how a final product presents when processed at this grade of water is key to meeting FDA expectations. That is, understand the endotoxin results on a device from the worst-case BET level. And, if there are multiple units or components of the same device implanted, the sum total of the endotoxins should meet the BET limit as if it were a single device.

It should be noted that a depyrogenation process such as incineration could be used to remedy endotoxin adulteration. However, it is difficult to remove endotoxins from medical devices once contaminated due to the high affinity that LPS has for certain surfaces such as metals. This strong adhesion makes depyrogenation problematic and potentially harmful to the device itself. It is easier and more economical to maintain an endotoxin-free process rather than to remediate an adulterated medical device.

What Is Purified Water?

Gram-negative flora can flourish in water, air, and food. For medical device manufacturing, the greatest endotoxin concern is with water that has direct product contact. Gram-negative bacteria can thrive in water that has minimal nutrients in the form of carbon4. High purity water is an absolute essential ingredient to a medical device and biases surgical outcomes toward success.

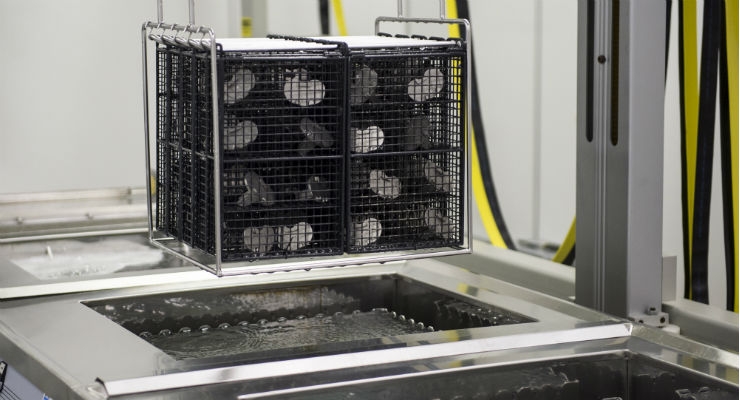

High purity water for processing of medical devices is essentially a very clean solvent. Water a solvent? Yes, water is the universal solvent, especially when it is deionized. Clean, deionized water facilitates the following:

High purity water is essential in the cleaning of medical devices and aids in the prevention of biological contamination.

How Do You Get There?

High purity water usually starts out as potable water containing chlorination to control bacterial growth. It will still have some level of endotoxins associated with it. Depending on the water source, this can range from undetectable to 1,250 ng/mL (12,500 EU/mL)5. If the source water is above 50 EU/mL, an ultrafiltration system should be considered to facilitate a 3–4 logarithmic reduction in BET prior to the purification process.

The potable water first gets pre-filtered to remove any solids and then gets softened to remove inorganic minerals such as calcium and magnesium as hard water interferes with cleaning processes and with the water purification process. This water is then passed through carbon beds to remove organic compounds and chlorine. Following that step, the water is filtered again to a 5-micron level to remove any remaining sediments prior to the purification process.

The purification process can be distillation or reverse osmosis (RO). For large-demand medical device cleaning systems, RO is a more economical method to produce high purity water in bulk. The RO process uses a pressure pump to overcome osmotic pressure. The process is dependent on cross-membrane velocity and the resultant water is stored for distribution.

The water created by the reverse osmosis system is then polished prior to distribution to the points of use. It is deionized through ion exchange resins; organic polymer chains that have either positive or negative fixed charges. The anions and cations attract minerals of the opposite charge, effectively removing the balance of organic and inorganic molecules from the water. Typically, ultraviolet light at a wavelength of 245 nanometers is then used to further disinfect the water. At this wavelength, the DNA of bacteria is most receptive to disruption and results in cell death.

Finally, the water is passed through sub-micron filter membranes with a pore size of 0.05 micron. This pore size is appropriate to capture endotoxins that are in the range of 10-20 kDa. Filter cartridges at this size capture 100 percent of endotoxins up to a challenge condition of 5 EU/mL.

This purification process results in deionized, high purity water that is essentially endotoxin free. The medical device implant cleaned with this grade of water should experience less aseptic loosening, promote osteointegration, and result in fewer surgical revisions.

One Final Caveat

There are mechanisms of contamination that are not obviously connected to water-based processes. Packaging materials, specifically lids that are designed to adhere to thermoformed trays, typically use a structural adhesive. The most widely used adhesives are water-based emulsions. These emulsions, if not made with purified water, can be a source of endotoxins that could ultimately contaminate a medical device when it is opened for use.

References

1 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2607446/

2 http://www.scielo.br/pdf/reeusp/v50n3/0080-6234-reeusp-50-03-0405.pdf

3 https://www.ncbi.nlm.nih.gov/pubmed/15449253

4 https://www.ncbi.nlm.nih.gov/pubmed/11537832

5 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC170068/

James Dwyer joined Millstone in 2017. Prior to joining Millstone, he held leadership roles at Mangar, C.R. Bard, and Johnson & Johnson. Dwyer is a certified packaging professional with over 25 years of experience in medical device engineering and operations. He received a bachelor of science degree in Industrial and Systems Engineering from Florida International University.

Endotoxins are mostly found in the cell wall (outer membrane) of Gram-negative bacteria. Endotoxins are lipopolysaccharides and the Lipid A portion of the heteropolysaccharide chain is responsible for the toxicity. The Lipid A is a powerful biological response modifier that can negatively stimulate the mammalian immune system. Endotoxins are constantly shed from viable gram-bacteria and when a gram-negative bacterium undergoes lysis, the entirety of its endotoxins is released from the cell into the immediate environment.

The FDA issued guidance on endotoxins in June of 2012. In this guidance, the CDRH adopted the USP Endotoxin Reference Standard and limits for medical device extracts. This standard expresses limits in units of EU, which is a measure of biological activity. Endotoxins vary in their potency to mass ratio; however, one EU equates to, approximately, 0.1-0.2 nanograms of endotoxin per ml of water. There are many caveats around this mass claim, however, it provides a rough correlation.

This guidance provides recommendations based upon the FDA’s current thinking. Specifically, it recommends an extraction volume limit of 0.5 EU/mL or 20 EU/device for devices that contact the cardiovascular system and lymphatic system directly or indirectly. For devices in contact with cerebrospinal fluid, the limit is 0.06 EU/mL or 2.15 EU/device. The limits for interocular devices is lower still at 0.215 EU/device. Most orthopedic devices fall into the less stringent limit of 20 EU/device. USP Chapter <161> Transfusion and Infusion Assemblies and Similar Medical Devices provide these limits.

Quality by design concepts are specifically addressed in the FDA guidance. The medical device manufacturer’s strategy for endotoxins should be based upon product and process knowledge. A comprehensive understanding of the potential sources of endotoxin contamination and monitoring of these sources are essential to ensure consistent final-product quality.

The United States Pharmacopeia (USP) <1231> can be a guide for a company’s USP water system whether it is utilizing a purified water system based upon reverse osmosis technology or distillation. However, there is no specification for bacterial endotoxins for purified water. So, the default is to utilize the more stringent specifications of WFI (water for injection). The WFI specification for endotoxins is 0.25 EU/mL. Understanding how a final product presents when processed at this grade of water is key to meeting FDA expectations. That is, understand the endotoxin results on a device from the worst-case BET level. And, if there are multiple units or components of the same device implanted, the sum total of the endotoxins should meet the BET limit as if it were a single device.

It should be noted that a depyrogenation process such as incineration could be used to remedy endotoxin adulteration. However, it is difficult to remove endotoxins from medical devices once contaminated due to the high affinity that LPS has for certain surfaces such as metals. This strong adhesion makes depyrogenation problematic and potentially harmful to the device itself. It is easier and more economical to maintain an endotoxin-free process rather than to remediate an adulterated medical device.

What Is Purified Water?

Gram-negative flora can flourish in water, air, and food. For medical device manufacturing, the greatest endotoxin concern is with water that has direct product contact. Gram-negative bacteria can thrive in water that has minimal nutrients in the form of carbon4. High purity water is an absolute essential ingredient to a medical device and biases surgical outcomes toward success.

High purity water for processing of medical devices is essentially a very clean solvent. Water a solvent? Yes, water is the universal solvent, especially when it is deionized. Clean, deionized water facilitates the following:

- Alkaline cleaning solutions, such as CIP 100 and Alconox, work more efficiently as they don’t need to compensate for mineral content of the water.

- Since there is no mineral content, there is no post-clean spotting or residue.

- The ultrasonics are able to cavitate more efficiently since there is no interference of suspended particulate.

- The absence of inorganic compounds creates a hypotonic environment that facilitates the removal of part’s contamination.

- Final rinsing of the devices is more efficient.

High purity water is essential in the cleaning of medical devices and aids in the prevention of biological contamination.

How Do You Get There?

High purity water usually starts out as potable water containing chlorination to control bacterial growth. It will still have some level of endotoxins associated with it. Depending on the water source, this can range from undetectable to 1,250 ng/mL (12,500 EU/mL)5. If the source water is above 50 EU/mL, an ultrafiltration system should be considered to facilitate a 3–4 logarithmic reduction in BET prior to the purification process.

The potable water first gets pre-filtered to remove any solids and then gets softened to remove inorganic minerals such as calcium and magnesium as hard water interferes with cleaning processes and with the water purification process. This water is then passed through carbon beds to remove organic compounds and chlorine. Following that step, the water is filtered again to a 5-micron level to remove any remaining sediments prior to the purification process.

The purification process can be distillation or reverse osmosis (RO). For large-demand medical device cleaning systems, RO is a more economical method to produce high purity water in bulk. The RO process uses a pressure pump to overcome osmotic pressure. The process is dependent on cross-membrane velocity and the resultant water is stored for distribution.

The water created by the reverse osmosis system is then polished prior to distribution to the points of use. It is deionized through ion exchange resins; organic polymer chains that have either positive or negative fixed charges. The anions and cations attract minerals of the opposite charge, effectively removing the balance of organic and inorganic molecules from the water. Typically, ultraviolet light at a wavelength of 245 nanometers is then used to further disinfect the water. At this wavelength, the DNA of bacteria is most receptive to disruption and results in cell death.

Finally, the water is passed through sub-micron filter membranes with a pore size of 0.05 micron. This pore size is appropriate to capture endotoxins that are in the range of 10-20 kDa. Filter cartridges at this size capture 100 percent of endotoxins up to a challenge condition of 5 EU/mL.

This purification process results in deionized, high purity water that is essentially endotoxin free. The medical device implant cleaned with this grade of water should experience less aseptic loosening, promote osteointegration, and result in fewer surgical revisions.

One Final Caveat

There are mechanisms of contamination that are not obviously connected to water-based processes. Packaging materials, specifically lids that are designed to adhere to thermoformed trays, typically use a structural adhesive. The most widely used adhesives are water-based emulsions. These emulsions, if not made with purified water, can be a source of endotoxins that could ultimately contaminate a medical device when it is opened for use.

References

1 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2607446/

2 http://www.scielo.br/pdf/reeusp/v50n3/0080-6234-reeusp-50-03-0405.pdf

3 https://www.ncbi.nlm.nih.gov/pubmed/15449253

4 https://www.ncbi.nlm.nih.gov/pubmed/11537832

5 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC170068/

James Dwyer joined Millstone in 2017. Prior to joining Millstone, he held leadership roles at Mangar, C.R. Bard, and Johnson & Johnson. Dwyer is a certified packaging professional with over 25 years of experience in medical device engineering and operations. He received a bachelor of science degree in Industrial and Systems Engineering from Florida International University.