Ramsey Stevens, CEO of nano3Dprint05.08.23

A recent study from Vantage Market Research reports that the 3D-printed footwear market is expected to grow by $1972.58 million at a CAGR of 19.72% from 2022-2027.

3D-printed solutions open new opportunities for integrating next-generation technology in footwear, as evidenced by recent additive manufacturing developments in healthcare, including those from ETH Zurich, Empa and EPFL, who 3D-printed insoles with embedded sensors.

Furthermore, with the increasing demand for 3D-printed insoles for diabetic patients, professional athletes and orthopedic patients, additive manufacturing is leading the way for innovations in orthopedic footwear.

However, this process has limitations.

If the last becomes defective — like breaking or warping under pressure — while fabricating the orthopedics, it can cause complexities in the manufacturing process. Because lasts are custom milled by hand, there is no process to make an “identical” one. Thus, orthopedic shoes may have to be discarded mid-manufacturing; a new last must be created; and the original shape may be impossible to reproduce.

Additionally, traditional manufacturers cannot always create the precise design required by the patient; and, because clinicians are not involved in the process, small details are often overlooked. If a patient has multiple conditions or unique orthopedic abnormalities, it’s more likely that the orthopedic shoes will not fit comfortably. This can result in patients delaying treatment or risk worsening their condition.

Design limitations, lengthy timelines and cost-intensive manufacturing have opened the door for new innovations, such as the integration of next-generation technologies via 3D printing in orthopedic footwear that can further improve orthopedics.

3D printing eliminates reliance on third-party manufacturing, resulting in a more cost-effective process that can be performed in-office by a clinician. The patient and clinician can compare the orthopedic designs to the patient’s condition for customization, which takes into consideration individual pressure points, ulcers or growths, as well as other complications stemming from their conditions.

Additionally, direct-write printing technology allows for sensors to be embedded directly within footwear, casts and prosthetics, providing new usage opportunities. The process involves a micro-dispenser that applies the exact amount of materials, like inks and high-viscosity pastes, needed to create a print on a substrate. It allows for the creation of complex shapes using multiple materials and is most commonly used to produce electronic sensing applications.

Some 3D print footwear companies now allow patients to order 3D-printed insoles directly. This direct-to-consumer model offers more options for materials, color and design, so patients can wear more fashionable sneakers customized for their orthopedic needs.

Embedded sensors in custom orthopedic insoles measure patient pressure points by collecting data that converts mechanical pressure into electrical signals. The sensors then report the data to an interface in the sole of the shoe, which can subsequently be analyzed. This data can be utilized to monitor patient gait as well as to diagnose severe illnesses like Parkinson’s disease, cancer, diabetes and dementia. The data can also help clinicians detect early warning signs of injuries and help them build prevention plans.

Customization also leads to an increase in patient comfort and ultimately a stronger desire to complete treatment.

For example, The Billi Research Lab, with support from Luskin Orthopaedic Institute for Children, is utilizing direct-write technology to print a smart electronic package for casts. Seamlessly embeddable 3D-printed circuits and sensors will enable the complete integration and intelligent distribution of the battery and wiring, eliminating the need for external obtrusive components.

Further, Exer Health says that 3D printing enables clinicians to design customized anatomical models that simulate surgical procedures to determine the best approach for their patients. These models can help identify potential issues — like improperly fitted implants — that may arise during surgery, even before a patient steps into the operating room. Surgeons can also use these models to better explain what surgery will include; this can ease patient anxiety and educate them about preoperative preparations, surgical process, and recovery.

Personalized 3D-printed orthopedic implants result in improved function and stronger structure, as compared to other traditionally manufactured options. Rapid prototyping and on-demand 3D printing have faster production timelines and enable changes to be made to implants that are tailored to the patient’s body. Customized biomaterials made via 3D printing increase patient comfort and can result in less blood loss during surgery. Thus, patients are less likely to be discharged to an acute care facility post-surgery, further simplifying the recovery process.

Gait diagnostics is important in identifying normal or pathological walking, trotting or running patterns and is used in rehabilitation, physical therapy, competition preparation and exercise training.

With enough detailed gait analysis during rehabilitation, it is possible to determine the patient's degree of recovery after surgery and tailor appropriate treatment.

During treatment, the data can help to hold patients accountable. Clinicians can see when treatment therapies, like physical therapy, took place and how the patient’s body reacted. Clinicians can also work with physical therapists to adapt treatment plans for quicker, more effective treatment timelines.

Via 3D printing, sensors can be implanted directly on living tissues such as bone, cartilage, tendons and skin, which then provide biofeedback to help advance understanding of the patient’s health status and tissue response to treatment.

While still in the early stages, many printers, including nano3Dprint’s A2200 Multi-Materials Printer and Redwire Space’s BioFabrication Facility have been used in leading research and developments.

As 3D printing technology continues to evolve, more applications will further drive innovation. It’s imperative that healthcare providers become knowledgeable about the benefits of 3D printing in orthopedic footwear.

Ramsey Stevens is CEO of nano3Dprint, a next-generation additive manufacturing solutions provider, and founder of Carbon Design Innovations (CDI). He is a researcher and leader in the development and use of carbon nanotubes (CNTs). He can be reached at info@nano3dprint.com.

3D-printed solutions open new opportunities for integrating next-generation technology in footwear, as evidenced by recent additive manufacturing developments in healthcare, including those from ETH Zurich, Empa and EPFL, who 3D-printed insoles with embedded sensors.

Furthermore, with the increasing demand for 3D-printed insoles for diabetic patients, professional athletes and orthopedic patients, additive manufacturing is leading the way for innovations in orthopedic footwear.

Traditional Orthopedics Manufacturing and Its Limitations

Typically, orthopedic footwear is produced by third-party companies that design prescribed orthopedics for medical professionals and deliver the final product directly to the patient. To begin the manufacturing process, a three-dimensional mold called a “last,” is created. Lasts, which are made from materials like wood, cast iron and high-density plastics, are crucial for tailoring orthopedic shoes to the patient’s exact needs.However, this process has limitations.

If the last becomes defective — like breaking or warping under pressure — while fabricating the orthopedics, it can cause complexities in the manufacturing process. Because lasts are custom milled by hand, there is no process to make an “identical” one. Thus, orthopedic shoes may have to be discarded mid-manufacturing; a new last must be created; and the original shape may be impossible to reproduce.

Additionally, traditional manufacturers cannot always create the precise design required by the patient; and, because clinicians are not involved in the process, small details are often overlooked. If a patient has multiple conditions or unique orthopedic abnormalities, it’s more likely that the orthopedic shoes will not fit comfortably. This can result in patients delaying treatment or risk worsening their condition.

Design limitations, lengthy timelines and cost-intensive manufacturing have opened the door for new innovations, such as the integration of next-generation technologies via 3D printing in orthopedic footwear that can further improve orthopedics.

Additive Manufacturing Provides New Solutions

Additive manufacturing of orthopedic footwear is a streamlined process that can be optimized from patient data. Clinicians gather data via 3D scans of the patient’s foot, photography and manual measurements. The scans are then turned into digital renderings, which can be uploaded to a CAD software platform for 3D printing, ensuring accuracy in fit and sizing.3D printing eliminates reliance on third-party manufacturing, resulting in a more cost-effective process that can be performed in-office by a clinician. The patient and clinician can compare the orthopedic designs to the patient’s condition for customization, which takes into consideration individual pressure points, ulcers or growths, as well as other complications stemming from their conditions.

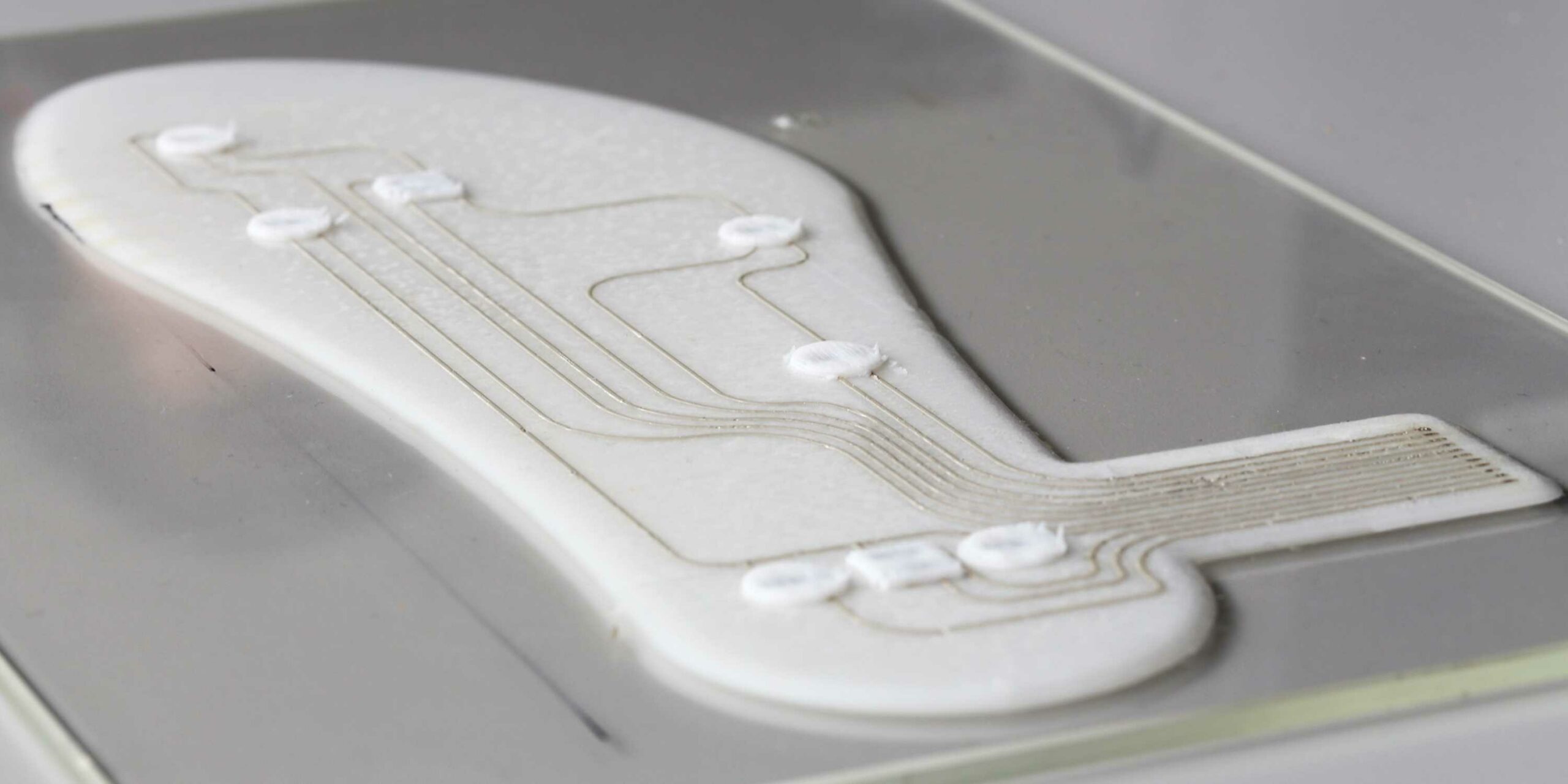

Additionally, direct-write printing technology allows for sensors to be embedded directly within footwear, casts and prosthetics, providing new usage opportunities. The process involves a micro-dispenser that applies the exact amount of materials, like inks and high-viscosity pastes, needed to create a print on a substrate. It allows for the creation of complex shapes using multiple materials and is most commonly used to produce electronic sensing applications.

3D-Printed Insoles

For patients with less severe conditions or those who don’t want to replace their regular footwear completely, customized 3D-printed insoles can be developed to correct or alleviate pain.Some 3D print footwear companies now allow patients to order 3D-printed insoles directly. This direct-to-consumer model offers more options for materials, color and design, so patients can wear more fashionable sneakers customized for their orthopedic needs.

Embedded sensors in custom orthopedic insoles measure patient pressure points by collecting data that converts mechanical pressure into electrical signals. The sensors then report the data to an interface in the sole of the shoe, which can subsequently be analyzed. This data can be utilized to monitor patient gait as well as to diagnose severe illnesses like Parkinson’s disease, cancer, diabetes and dementia. The data can also help clinicians detect early warning signs of injuries and help them build prevention plans.

Customization also leads to an increase in patient comfort and ultimately a stronger desire to complete treatment.

Orthopedic and Surgical Applications of 3D-Printing

3D printing in orthopedic treatments goes beyond just footwear. Some patients may require orthopedic surgery as part of their treatment, and 3D printing offers many benefits for pre-surgery planning, personalized implants and customized prosthetics.For example, The Billi Research Lab, with support from Luskin Orthopaedic Institute for Children, is utilizing direct-write technology to print a smart electronic package for casts. Seamlessly embeddable 3D-printed circuits and sensors will enable the complete integration and intelligent distribution of the battery and wiring, eliminating the need for external obtrusive components.

Further, Exer Health says that 3D printing enables clinicians to design customized anatomical models that simulate surgical procedures to determine the best approach for their patients. These models can help identify potential issues — like improperly fitted implants — that may arise during surgery, even before a patient steps into the operating room. Surgeons can also use these models to better explain what surgery will include; this can ease patient anxiety and educate them about preoperative preparations, surgical process, and recovery.

Personalized 3D-printed orthopedic implants result in improved function and stronger structure, as compared to other traditionally manufactured options. Rapid prototyping and on-demand 3D printing have faster production timelines and enable changes to be made to implants that are tailored to the patient’s body. Customized biomaterials made via 3D printing increase patient comfort and can result in less blood loss during surgery. Thus, patients are less likely to be discharged to an acute care facility post-surgery, further simplifying the recovery process.

How 3D-Printing Impacts Recovery and Treatment

Monitoring progress during treatment and recovery is critical. Embedded sensors can monitor progress during treatment and recovery and provide clinicians with more data. This data can report real-world applications and patient reactions to their environment. By knowing what triggers a patient's symptoms, clinicians can provide a faster and more accurate diagnosis.Gait diagnostics is important in identifying normal or pathological walking, trotting or running patterns and is used in rehabilitation, physical therapy, competition preparation and exercise training.

With enough detailed gait analysis during rehabilitation, it is possible to determine the patient's degree of recovery after surgery and tailor appropriate treatment.

During treatment, the data can help to hold patients accountable. Clinicians can see when treatment therapies, like physical therapy, took place and how the patient’s body reacted. Clinicians can also work with physical therapists to adapt treatment plans for quicker, more effective treatment timelines.

Future of 3D-Printed Orthopedics

Best suited for outdoor assessments, thermal sensors can help clinicians identify and analyze how temperature impacts such patient conditions as swelling, aches and more. This can lead to new innovations in treatment and a better understanding of patient symptoms.Via 3D printing, sensors can be implanted directly on living tissues such as bone, cartilage, tendons and skin, which then provide biofeedback to help advance understanding of the patient’s health status and tissue response to treatment.

While still in the early stages, many printers, including nano3Dprint’s A2200 Multi-Materials Printer and Redwire Space’s BioFabrication Facility have been used in leading research and developments.

Conclusion

3D printing provides streamlined, cost-effective and timely orthopedics manufacturing. The variety of available 3D printing applications provides groundbreaking innovations that will improve care.As 3D printing technology continues to evolve, more applications will further drive innovation. It’s imperative that healthcare providers become knowledgeable about the benefits of 3D printing in orthopedic footwear.

Ramsey Stevens is CEO of nano3Dprint, a next-generation additive manufacturing solutions provider, and founder of Carbon Design Innovations (CDI). He is a researcher and leader in the development and use of carbon nanotubes (CNTs). He can be reached at info@nano3dprint.com.