Advancing Healthcare Innovations

The integration of desktop manufacturing machines like 3D printers and CNC waterjets directly in hospitals, clinics, and rehab facilities has unlocked greater healthcare innovation. These machines can produce anatomical models for preoperative planning, customized surgical guides based on body scans, parts designed to match body scans, dental prostheses from intraoral scans, and personalized surgical instruments tailored to surgeons' specifications. For device manufacturers and designers, these compact machines enable the production of one-off pieces in a fraction of the time it would traditionally take, facilitating localized and customized treatments.

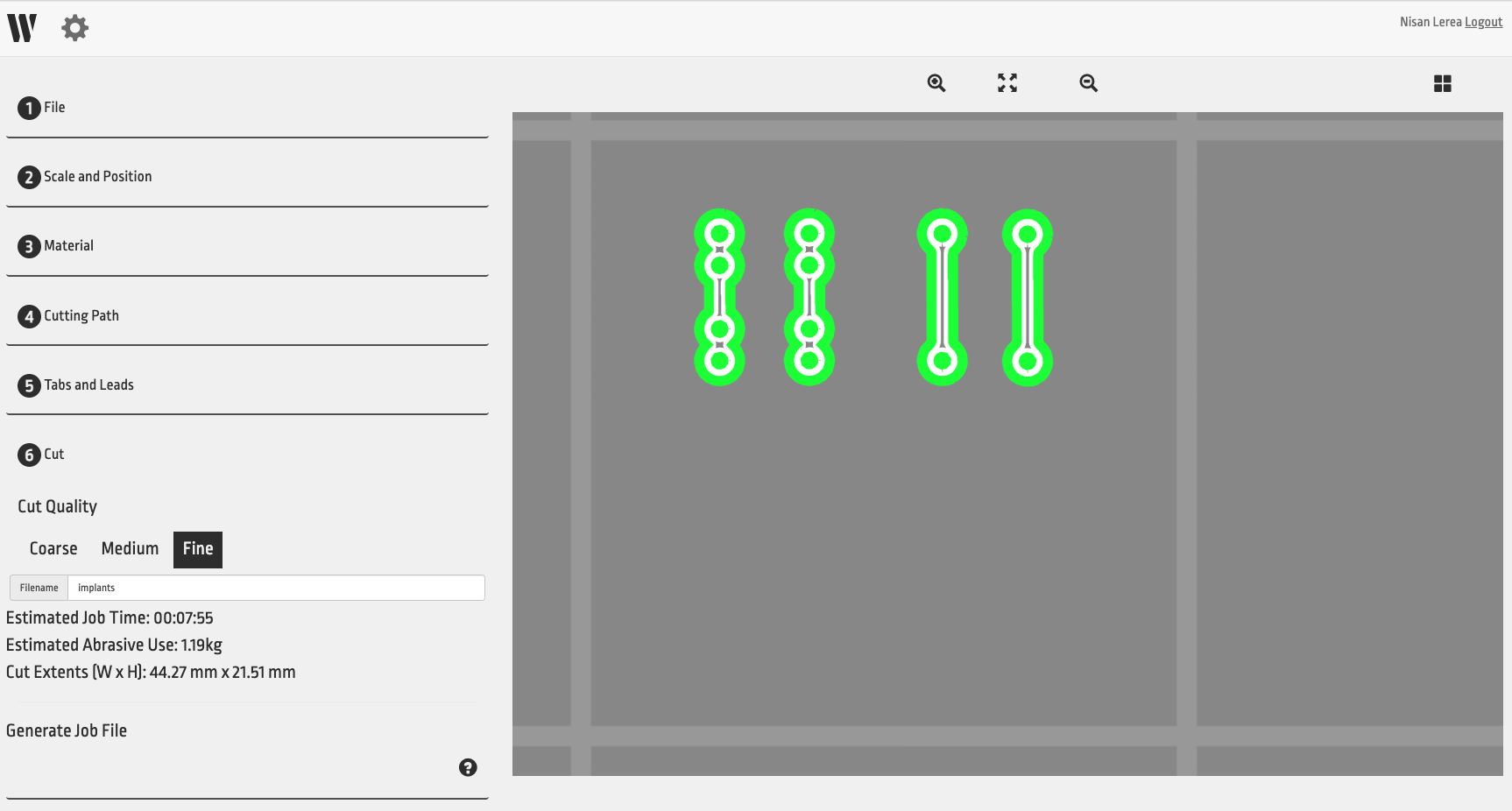

Orthopedic implants, shown in software for CNC waterjet cutting.

Streamlined Prototyping

Prototyping is a crucial step in the creation of any medical device. Traditionally, design engineers have faced challenges due to limited access to industrial manufacturing tools, especially when it comes to cutting certain materials. This limitation often leads to outsourcing specific custom pieces for prototypes, resulting in lengthy bottlenecks. However, compact tools like desktop-sized waterjet cutters provide a solution by enabling engineers to create fully functional implant prototypes in-house. This eliminates the need for outsourcing and significantly reduces the time required for iterations and alterations.To have the most extensive range of in-house prototyping capabilities, modern prototype shops require a combination of compact subtractive and additive manufacturing machinery. Compact 3D printers work alongside small-format waterjets to produce parts in resin materials using additive manufacturing, and cut prototype parts out of metals and specialized materials using subtractive manufacturing, both in-house. This combination allows for fast iterations and early design adjustments, reducing the cost of changes and enabling engineers to de-risk their designs during the initial stages of development.

Small format waterjet machine cutting sample parts out of carbon fiber.

Accelerating Production

High-volume medical device manufacturing requires precision tools and jigs to guide and control mass production. Whenever parts or machines undergo a change, the corresponding tooling must also be updated.Traditional outsourcing of tooling can be time-consuming, costly, and prone to errors. Compact desktop CNC manufacturing machines offer an alternative by enabling the creation of tooling and jigs in-house when needed. This reduces manufacturing expenses and downtime while accelerating time-to-market. For example, a medical device manufacturer with a need to replace tooling on sixty industrial machines can leverage a compact CNC waterjet to produce new tooling in-house in a fraction of the time it would take to outsource.

In the face of increasing pressure for innovation, competition, and high-volume production, compact CNC manufacturing tools are proving to be vital enablers for medical device manufacturers. Their smaller footprint, affordability, and ease of operation make them indispensable in accelerating and de-risking the design phase, as well as facilitating in-house production of medical devices.

Specialized Materials Processing

The medical device industry often employs specialized materials that require specific tools for processing. Desktop CNC manufacturing machinery has the capability to work with these industry-specific materials. For example, waterjets excel in cutting sheets of specialized plastics and metals, including biocompatible, sterilization-resistant, and X-ray opaque materials such as PEEK, PPSU, PSU, and POM. These materials, essential for orthotic devices, prosthetics, gas pathway connectors, and adapters, are not compatible with compact 3D printers due to process restrictions.Furthermore, the integration of compact subtractive and additive manufacturing technologies provides medical device manufacturers with a comprehensive prototyping solution. The combination of these technologies enables faster iterations, early design adjustments, and reduced costs, empowering engineers to optimize their designs before moving to mass production.

The use of compact machines has expanded the horizons of medical device manufacturing by facilitating the production of customized treatments. Hospitals, clinics, and labs can now create anatomical models, surgical guides, and personalized surgical instruments in-house, offering tailored solutions for patients and enhancing healthcare outcomes. The ability to produce one-off pieces quickly and efficiently has transformed the way medical devices are developed and delivered.

Compact digital CNC waterjet machine by WAZER.

In conclusion, compact manufacturing technologies are revolutionizing the medical device manufacturing space. They enhance the prototyping process, enable the use of specialized materials, facilitate localized and customized treatments, and keep high-volume production lines running smoothly. As the medical device industry continues to evolve, the adoption of these compact tools will become increasingly crucial in meeting the industry's demands for innovation, quality, and cost-effectiveness.

Nisan Lerea is the Co-Founder and CEO of WAZER and an inventor of the world’s first desktop waterjet cutter. A consummate “maker,” Nisan spent many hours in the machine shop during his time at the University of Pennsylvania working on projects including a Formula 1-style race car. He needed to cut sheet metal but only had access to laser cutting, which could only cut soft materials. Nisan set out to solve the problem, inventing the first small-scale waterjet that would become WAZER. While working as a mechanical engineer, Nisan realized that other designers and engineers still faced barriers to waterjet cutting, so he teamed up with former colleague and fellow Penn Engineering student Matt Nowicki to launch WAZER in 2016.